Rating:

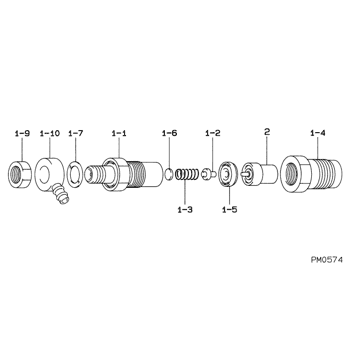

Information injection nozzle Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$84.61

13 Nov 2024

KR: Adabus

DN12SD12 Fuel Injector Nozzle 093400-0100,0434250027,105000-1600 for Sachs ISHIKAIMA for Kubota 6Pieces/Lot

Generic

Generic

$20.50

15 Oct 2024

KR: Adabus

Injector Nozzle DN12SD12 093400-0100 0434250027 105000-1600 Compatible with for Kubota Tractor B5200D B5200E B7100 B7100HST-DT

Generic Package Includes: Injector Nozzle * 1 | Condition: Aftermarket Product | Not Sure This Part is Suitable to We'll Reply You as soon as Possible || Compatible with For Kubota Diesel Engine D750 || Compatible with For Kubota Tractor B5200D B5200E B7100 B7100HST-DT B7100HST-E B7100HST-II-DT

Generic Package Includes: Injector Nozzle * 1 | Condition: Aftermarket Product | Not Sure This Part is Suitable to We'll Reply You as soon as Possible || Compatible with For Kubota Diesel Engine D750 || Compatible with For Kubota Tractor B5200D B5200E B7100 B7100HST-DT B7100HST-E B7100HST-II-DT

Include in ##:

09350-01560

as NOZZLE ASSY

Cross reference number

Part num

Firm num

Firm

Name

093400-1160

105000-1600

ZEXEL

INJECTION NOZZLE

093400-1160

0434250027

BOSCH

INJECTION NOZZLE

093400-1160

0434250992

BOSCH

INJECTION NOZZLE

093400-1160

5643014

CAV

INJECTION NOZZLE

093400-1160

5643085

CAV

INJECTION NOZZLE

093400-1160

ADN12SD12

AMBAC

INJECTION NOZZLE

Information:

Start By:a. remove radiator

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Loosen bolt (4), bolt (5), and bolt (6). Remove belts (3).2. Remove bolts (2) and fan (1). 3. Remove bolt (7) and washer (8). Put enough spacers (10) on bolt (7) to get approximately 3.18 mm (.125 in) of clearance between washer (8) and vibration damper and pulley assembly (9). Install bolt (7), washer (8), and spacers (10).

If spacers (10) are not used, damage to the bolt and/or crankshaft can result when the vibration damper and pulley are removed from the crankshaft.

4. Install tool (A) as shown, and loosen vibration damper and pulley assembly (9).5. Remove tool (A), bolt (7), washer (8), spacers (10), and vibration damper and pulley assembly (9). 6. If necessary, remove bolts (11) and vibration damper (12). The following steps are to install the crankshaft vibration damper and pulley. Inspect the vibration damper housing for leakage or dents (damage housing). If either condition exists, a replacement of the vibration damper must be made.7. Install vibration damper (12) on pulley (13). Install bolts (11).8. Install vibration damper and pulley assembly (9) and install bolt (7), spacers (10) and washer (8).

The flat side of washer (8) must be installed toward vibration damper and pulley assembly (9).

9. Tighten bolt (7) to a torque of 284 to 340 N m (210 to 250 lb ft). Hit bolt (7) with a hammer and retighten to a torque of 284 to 340 N m (210 to 250 lb ft).10. Position belts (3). Tighten bolts (4), (5), and (6). Use a belt tension gauge and make an adjustment of the belts. Measure the belt farthest from the engine. Tighten new belts until the gauge indication is 534 22 N (120 5 lb ft). Operate the engine at high idle for a minimum of 30 minutes after installing radiator and guards. Make another adjustment of the belt tension. The correct gauge indication for a used belt is 400 44 N (90 10 lb.). Tighten bolt (4), bolt (5), and bolt (6).11. Install fan (1) and bolt (2).End By:a. install radiator

Perform Scheduled Oil Sampling on oil wetted compartments after performing service work to check for contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

1. Loosen bolt (4), bolt (5), and bolt (6). Remove belts (3).2. Remove bolts (2) and fan (1). 3. Remove bolt (7) and washer (8). Put enough spacers (10) on bolt (7) to get approximately 3.18 mm (.125 in) of clearance between washer (8) and vibration damper and pulley assembly (9). Install bolt (7), washer (8), and spacers (10).

If spacers (10) are not used, damage to the bolt and/or crankshaft can result when the vibration damper and pulley are removed from the crankshaft.

4. Install tool (A) as shown, and loosen vibration damper and pulley assembly (9).5. Remove tool (A), bolt (7), washer (8), spacers (10), and vibration damper and pulley assembly (9). 6. If necessary, remove bolts (11) and vibration damper (12). The following steps are to install the crankshaft vibration damper and pulley. Inspect the vibration damper housing for leakage or dents (damage housing). If either condition exists, a replacement of the vibration damper must be made.7. Install vibration damper (12) on pulley (13). Install bolts (11).8. Install vibration damper and pulley assembly (9) and install bolt (7), spacers (10) and washer (8).

The flat side of washer (8) must be installed toward vibration damper and pulley assembly (9).

9. Tighten bolt (7) to a torque of 284 to 340 N m (210 to 250 lb ft). Hit bolt (7) with a hammer and retighten to a torque of 284 to 340 N m (210 to 250 lb ft).10. Position belts (3). Tighten bolts (4), (5), and (6). Use a belt tension gauge and make an adjustment of the belts. Measure the belt farthest from the engine. Tighten new belts until the gauge indication is 534 22 N (120 5 lb ft). Operate the engine at high idle for a minimum of 30 minutes after installing radiator and guards. Make another adjustment of the belt tension. The correct gauge indication for a used belt is 400 44 N (90 10 lb.). Tighten bolt (4), bolt (5), and bolt (6).11. Install fan (1) and bolt (2).End By:a. install radiator

Perform Scheduled Oil Sampling on oil wetted compartments after performing service work to check for contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.