Rating:

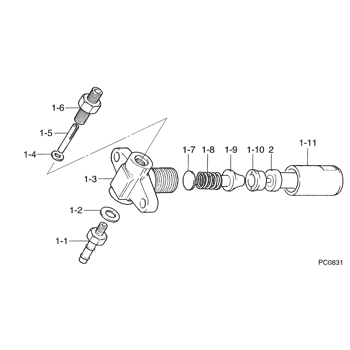

Information injection nozzle Denso

Nozzle Type:

ND-DN15S2

KUBOTA agricultural machine KND(R)90

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

Injector Nozzle 12 Pieces 093400-2910 093400-5571 105000-0010 105000-0020 105000-0110 105000-0260 Diesel Nozzle - (Color: 105000-0020)

Generic Color: 105000-0020

Generic Color: 105000-0020

Injector Nozzle 12 Pieces 093400-2910 093400-5571 105000-0010 105000-0020 105000-0110 105000-0260 Diesel Nozzle - (Color: 105000-0010)

Generic Color: 105000-0010

Generic Color: 105000-0010

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

093400-0120

105000-0110

ZEXEL

INJECTION NOZZLE

093400-0120

105000-0260

ZEXEL

INJECTION NOZZLE

093400-0120

0434200018

BOSCH

INJECTION NOZZLE

093400-0120

5642014

CAV

INJECTION NOZZLE

Information:

start by: a) remove vibration damper and pulley 1. Use tooling (A) to remove the crankshaft front seal from the timing gear cover. When a replacement of the front seal is made, a replacement of the wear sleeve is to be made also. 2. Put tool (B) in position in the seal bore as shown.3. Install tool (C) between tool (B) and the wear sleeve. Turn tool (C) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.4. Remove tool (B) and the wear sleeve by hand.5. Clean and make a preparation of the wear sleeve inside diameter and crankshaft outside diameter with 8M8060 Quick Cure Primer. Put 9S3265 Retaining Compound on the crankshaft outside diameter and wear sleeve inside diameter before the wear sleeve is installed on the crankshaft. 6. Put a small amount of clean oil on the lip of the seal. Install wear sleeve (2) and seal (1) on the crankshaft as shown with tools (D). If tools are not available, install the wear sleeve until it is .060 .020 in. (1.52 0.51 mm) (dimension "X") from the face of the crankshaft. Install the seal in the timing gear cover until the metal face of the seal is .090 .020 in. (2.29 0.51 mm) (dimension "Y") from the face of the crankshaft.end by: a) install vibration damper and pulleyRemove And Install Crankshaft Rear Seal And Wear Sleeve

start by:a) remove flywheel 1. Use tool (A) to remove crankshaft rear seal (1) from the flywheel housing. When a replacement of the rear seal is made, a replacement of the wear sleeve is to be made also.

TYPICAL EXAMPLE2. Put tool (B) in position in the seal bore as shown.3. Install tool (C) between tool (B) and the wear sleeve. Turn tool (C) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.4. Remove tool (B) and the wear sleeve by hand.5. Clean and make a preparation of the wear sleeve inside diameter and adapter outside diameter with 8M8060 Quick Cure Primer. Put 9S3265 Retaining Compound on the adapter outside diameter and wear sleeve inside diameter before the wear sleeve is installed on the adapter. Make sure the lip of the seal is toward the inside of the engine and the outside diameter bevel of the wear sleeve is toward the outside of the engine.6. Put a small amount of clean engine oil on the lip of the seal. Install the wear sleeve and the seal on the crankshaft as shown with tools (D).end by:a) install flywheel

start by:a) remove flywheel 1. Use tool (A) to remove crankshaft rear seal (1) from the flywheel housing. When a replacement of the rear seal is made, a replacement of the wear sleeve is to be made also.

TYPICAL EXAMPLE2. Put tool (B) in position in the seal bore as shown.3. Install tool (C) between tool (B) and the wear sleeve. Turn tool (C) until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.4. Remove tool (B) and the wear sleeve by hand.5. Clean and make a preparation of the wear sleeve inside diameter and adapter outside diameter with 8M8060 Quick Cure Primer. Put 9S3265 Retaining Compound on the adapter outside diameter and wear sleeve inside diameter before the wear sleeve is installed on the adapter. Make sure the lip of the seal is toward the inside of the engine and the outside diameter bevel of the wear sleeve is toward the outside of the engine.6. Put a small amount of clean engine oil on the lip of the seal. Install the wear sleeve and the seal on the crankshaft as shown with tools (D).end by:a) install flywheel