Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

TRUCK S05C-B

Engine

S05C-B

Serial start-end

0206-

Info

Injector Nozzle

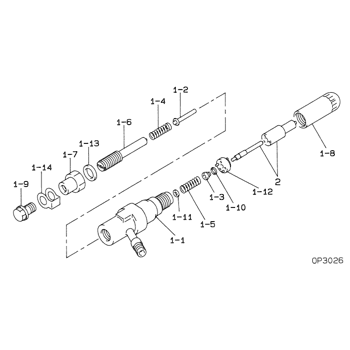

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-07610

HOLDER & NOZZLE SE

-0603

000

[01]

09350-07610

HOLDER & NOZZLE SE

0604-

Include in ##:

09350-07610

as HOLDER & NOZZLE SE

09350-07610 HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935007610 HINO

Nozzle

0934003370

First opm

16.67-17.45

First op

170.1-178.0

Second om

18.65-19.63

Second op

190.2-200.2

Torquen

58.8-68.6

Torque

6.0-7.0

Prelift

0.095-0.115

Max lift

0.3

Engine

TRUCK S05C-B

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-07610

HOLDER & NOZZLE SE

Information:

Measurement of Compression Pressure

Preparation For Inspection

Check the following before inspection.(1) Make sure that the engine oil, air cleaner, starter, battery, etc. are in normal operating condition.

Measurement of compression pressureInspection

(1) Move the control lever to the Stop position.(2) Remove the glow plugs from all cylinders, and attach the gage adapter and compression gage to the cylinder to be tested. (3) Crank the engine with the starter, and read the compression gage indication when the indication stabilizes.(4) If the measured compression pressure is lower than the limit, consider overhauling the engine.

(a) Measure the compression pressure in all cylinders.(b) As compression pressure varies with the engine speed, measure the engine speed at the same time.

Measure the compression pressure while the engine is running at 150 to 200 min-1. The oil and coolant temperatures should be between 20 and 30 °C [68 and 86°F].

(a) Measure the compression pressure at regular intervals to keep the record of changes in compression pressure.(b) Compression pressure will be slightly higher when the engine is new or immediately after an overhaul due to tight clearances of piston rings and valve seats, but it decreases to the standard level after the parts break in.

Preparation For Inspection

Check the following before inspection.(1) Make sure that the engine oil, air cleaner, starter, battery, etc. are in normal operating condition.

Measurement of compression pressureInspection

(1) Move the control lever to the Stop position.(2) Remove the glow plugs from all cylinders, and attach the gage adapter and compression gage to the cylinder to be tested. (3) Crank the engine with the starter, and read the compression gage indication when the indication stabilizes.(4) If the measured compression pressure is lower than the limit, consider overhauling the engine.

(a) Measure the compression pressure in all cylinders.(b) As compression pressure varies with the engine speed, measure the engine speed at the same time.

Measure the compression pressure while the engine is running at 150 to 200 min-1. The oil and coolant temperatures should be between 20 and 30 °C [68 and 86°F].

(a) Measure the compression pressure at regular intervals to keep the record of changes in compression pressure.(b) Compression pressure will be slightly higher when the engine is new or immediately after an overhaul due to tight clearances of piston rings and valve seats, but it decreases to the standard level after the parts break in.