Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL S6S-DT

Engine

S6S-DT

Serial start-end

0201-

Info

Injector Nozzle

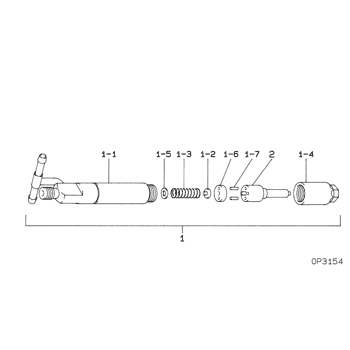

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-07600

HOLDER & NOZZLE SE

Include in ##:

09350-07600

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935007600 MITSUBISHI

Nozzle

0934008080

First opm

18.14-19.12

First op

185-195

Second om

-

Second op

-

Torquen

29.4

Torque

3.0

Prelift

-

Max lift

0.25

Engine

INDUSTRIAL S6S-DT

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-07600

HOLDER & NOZZLE SE

Information:

Disassembly

Rocker arms and rocker shaft disassembly sequence(1) Rocker cover(2) Rocker stay bolt(3) Rocker arm/rocker shaft assembly(4) Snap ring(5) Rocker arm(6) Rocker stay(7) Rocker spring(8) Rocker shaft Key Points For Disassembly(1) Removing Rocker Arm/Rocker Shaft Assembly

(a) Loosen the rocker arm adjusting screws by approximately one turn each.

Removing rocker stay bolt(b) Remove the rocker stay bolts, then remove the rocker arm/rocker shaft assembly.

Removing rocker arm/rocker shaft assembly(2) Disassembling Rocker Arm/Rocker Shaft Assembly

When removing the rocker arms, arrange them in a line matching their installed positions to ensure that they are later refitted in the correct sequence. The rocker arms must be refitted in their original positions to prevent changes in the clearances between the rocker arms and rocker shaft.

Disassembling rocker arm/rocker shaft assemblyInspection and Repair

Points to check rocker arm/rocker shaft assembly KEY POINTS FOR INSPECTION AND REPAIR Measuring Rocker Arm-to-Rocker Shaft ClearanceMeasure the rocker arms' inside diameters and the rocker shaft's outside diameter, and calculate the clearances from the measurements. Replace any rocker arm where the clearance exceeds the specified limit.

Measuring rocker arm inside diameter and rocker shaft outside diameterAssembly

Tightening torques and oil application locationsPerform assembly by following the disassembly sequence in reverse: KEY POINTS FOR ASSEMBLY(1) Assembling Rocker Arm/Rocker Shaft Assembly

Install each pair of rocker arms such that the identification mark (a hole with a diameter of 3 mm (0.12 in.)) is positioned on the side closer to the front of the engine.

Rocker shaft identification mark(2) Adjusting Valve Clearance

(a) Loosen the rocker arm nut, then adjust the clearance to the standard value using the adjusting screw and a thickness gauge. (b) Hold the adjusting screw in position while tightening the nut.

Adjusting valve clearance

When adjusting the valve clearances after performing disassembly and reassembly, turn the crankshaft two or three times then check again that the clearances are within specification.

Cylinder Head and Valves

Disassembly

Cylinder head and valve disassembly sequence(1) Push Road(2) Main Bolt(3) Sub-bolt(4) Cylinder head(5) Cylinder head gasket(6) Valve retainer lock(7) Retainer(8) Valve spring(9) Valve (intake/exhaust)(10) Valve stem seal(11) Valve guide (Remove if it appears defective.) Key Points For Disassembly(1) Removing Cylinder Head

(a) Withdraw the push rods.

Withdrawing push rods(b) Loosen the cylinder bolts in the sequence shown in the drawing. Go through the sequence two or three times, loosening the bolts a little each time. Do not completely remove any bolt in isolation.

Cylinder head bolt loosening sequence

In the event of a cylinder head fault, use a torque wrench to check the bolts for looseness before deciding to remove them.(c) Lift the cylinder head assembly straight upward to remove it.

Removing cylinder head assembly

If the cylinder head gasket sticks to the cylinder head assembly and cylinder block and prevents them being separated, tap the thickest parts on the sides of the cylinder head using a plastic-faced hammer.(2) Removing Valves and Valve Springs

(a) Use a valve lifter (commercially available) to compress the valve spring, then remove the valve lock.(b) Remove the retainer, spring and valve.

Removing valve spring

Keep together the valves and other parts for each cylinder after removing them. Do not allow parts for

Rocker arms and rocker shaft disassembly sequence(1) Rocker cover(2) Rocker stay bolt(3) Rocker arm/rocker shaft assembly(4) Snap ring(5) Rocker arm(6) Rocker stay(7) Rocker spring(8) Rocker shaft Key Points For Disassembly(1) Removing Rocker Arm/Rocker Shaft Assembly

(a) Loosen the rocker arm adjusting screws by approximately one turn each.

Removing rocker stay bolt(b) Remove the rocker stay bolts, then remove the rocker arm/rocker shaft assembly.

Removing rocker arm/rocker shaft assembly(2) Disassembling Rocker Arm/Rocker Shaft Assembly

When removing the rocker arms, arrange them in a line matching their installed positions to ensure that they are later refitted in the correct sequence. The rocker arms must be refitted in their original positions to prevent changes in the clearances between the rocker arms and rocker shaft.

Disassembling rocker arm/rocker shaft assemblyInspection and Repair

Points to check rocker arm/rocker shaft assembly KEY POINTS FOR INSPECTION AND REPAIR Measuring Rocker Arm-to-Rocker Shaft ClearanceMeasure the rocker arms' inside diameters and the rocker shaft's outside diameter, and calculate the clearances from the measurements. Replace any rocker arm where the clearance exceeds the specified limit.

Measuring rocker arm inside diameter and rocker shaft outside diameterAssembly

Tightening torques and oil application locationsPerform assembly by following the disassembly sequence in reverse: KEY POINTS FOR ASSEMBLY(1) Assembling Rocker Arm/Rocker Shaft Assembly

Install each pair of rocker arms such that the identification mark (a hole with a diameter of 3 mm (0.12 in.)) is positioned on the side closer to the front of the engine.

Rocker shaft identification mark(2) Adjusting Valve Clearance

(a) Loosen the rocker arm nut, then adjust the clearance to the standard value using the adjusting screw and a thickness gauge. (b) Hold the adjusting screw in position while tightening the nut.

Adjusting valve clearance

When adjusting the valve clearances after performing disassembly and reassembly, turn the crankshaft two or three times then check again that the clearances are within specification.

Cylinder Head and Valves

Disassembly

Cylinder head and valve disassembly sequence(1) Push Road(2) Main Bolt(3) Sub-bolt(4) Cylinder head(5) Cylinder head gasket(6) Valve retainer lock(7) Retainer(8) Valve spring(9) Valve (intake/exhaust)(10) Valve stem seal(11) Valve guide (Remove if it appears defective.) Key Points For Disassembly(1) Removing Cylinder Head

(a) Withdraw the push rods.

Withdrawing push rods(b) Loosen the cylinder bolts in the sequence shown in the drawing. Go through the sequence two or three times, loosening the bolts a little each time. Do not completely remove any bolt in isolation.

Cylinder head bolt loosening sequence

In the event of a cylinder head fault, use a torque wrench to check the bolts for looseness before deciding to remove them.(c) Lift the cylinder head assembly straight upward to remove it.

Removing cylinder head assembly

If the cylinder head gasket sticks to the cylinder head assembly and cylinder block and prevents them being separated, tap the thickest parts on the sides of the cylinder head using a plastic-faced hammer.(2) Removing Valves and Valve Springs

(a) Use a valve lifter (commercially available) to compress the valve spring, then remove the valve lock.(b) Remove the retainer, spring and valve.

Removing valve spring

Keep together the valves and other parts for each cylinder after removing them. Do not allow parts for