Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL SAA6D108E

Engine

SAA6D108E

Serial start-end

0105-

Info

Injector Nozzle

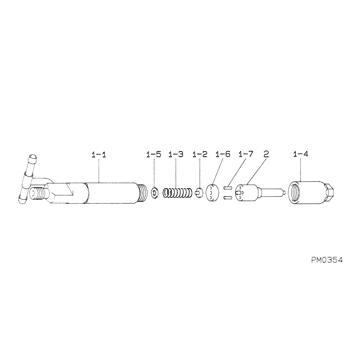

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-07540

HOLDER & NOZZLE SE

Include in ##:

09350-07540

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935007540 KOMATSU

Nozzle

0934007900

First opm

26.48-27.46

First op

270-280

Second om

-

Second op

-

Torquen

39.2-49.0

Torque

4.0-5.0

Prelift

-

Max lift

0.3

Engine

INDUSTRIAL SAA6D108E

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-07540

HOLDER & NOZZLE SE

Information:

17Sep2012

U-499

A-396

D-428

O-460

After Failure Only

PRODUCT SUPPORT PROGRAM FOR REPLACING FUEL INJECTORS ON CERTAIN AD55B UNDERGROUND ARTICULATED TRUCKS

1251 1290 PS52294

This Program can only be administered after a failure occurs.The decision whether to apply the Program is made by the dealer. When reporting the repair, use "PS52294" as the Part Numberand "7755" as the Group Number. Use "96" as the Warranty Claim Description Code and use "Z" as the SIMS Description Code.

The information supplied in this service letter may not be valid after the termination date of this program.Do not perform the work outlined in this Service Letter after the termination date without first contacting your Caterpillar product analyst.

TERMINATION DATE

30Sep2014

PROBLEM

The existing fuel injectors can experience solenoid valve poppet seizures or poppet binding within injector body due to excessive thermal expansion. If the existing fuel injector fails it can result in complaints of misfire and/or low power.

AFFECTED PRODUCT

Model Identification Number

AD55B JNW00101-00151, 153-155, 157-166, 168-199, 201-244, 246, 248-269, 272-275, 60250

PARTS NEEDED

Qty

Part Number Description

12 8S9191 BOLT

24 3565212 BOLT-12 POINT HD

12 3740751 INJECTOR GP-FUEL

In order to allow equitable parts availability to all participating dealers, please limit your initial parts order to not exceed 7% of dealership population. This is an initial order recommendation only, and the ultimate responsibility for ordering the total number of parts needed to satisfy the program lies with the dealer.

ACTION REQUIRED

A fuel injector is considered failed if the following troubleshooting Step 1 and Step 2 are completed and the problem is not resolved. Troubleshooting is not cover by this letter.

1. Ensure ECM software is current.

2. Perform the following procedures:

KENR5424 ? Troubleshooting

SENR9937 - Electronic Unit Injector ? Adjust

SENR9937 - Electronic Unit Injector - Test

3. Replace injector(s) as required.

If one or more injectors fail replace all injectors at the time of repair.

Refer to Disassembly and Assembly, RENR9217 for the removal and installation procedure of the unit injector.

8S-9191 Injector Hold Down Bolt must be replaced. Ensure that the proper torque is achieved, 55 +/- 10 Nm (41 +/- 7 lb ft).

356-5212 Rocker Arm Shaft Hold Down Bolts must be replaced. Ensure that proper torque procedure is adhered to.

1. Position rocker arm shaft assembly (4) , valve rocker arms (3) , and electronic unit injector rocker arms (1) as a unit with 124-2946 Lifting Bracket on the cylinder head.

Note: Apply clean engine oil to the underside of the bolt heads prior to installation.

2. Install bolts (2) and tighten to a torque of 55 +/- 5 Nm (41 +/- 4 lb ft). Tighten bolts (2) again to a torque of 55 +/- 5 Nm (41 +/- 4 lb ft). Turn bolts (2) for an additional 60 +/- 5 degrees. Tighten the bolts in the following sequence: 2, 3, 1, 4.

Image1

SERVICE CLAIM ALLOWANCES

Product smu/age whichever comes first Caterpillar