Rating:

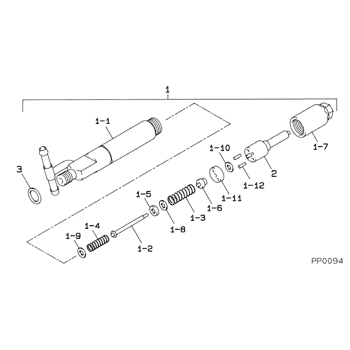

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

CANTER 4D34T6

Engine

4D34T6

Serial start-end

0012-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

HAOSHUN 4X Fuel Injector Compatible FOR Mitsubishi 4D34T 4D34 Engine ME215124 ME220255 093500-7500 093500-7510

HAOSHUN Part Name:Fuel Injector || Part Number:ME215124 ME220255 093500-7500 093500-7510 || APPlication: FOR Mitsubishi 4D34T 4D34 Engine || 1. Please leave your physical address (home or office address) but do not leave your P.O. Box address and ensure that your address and contact information are correct. || 2.Please make sure it will fit your machine before purchasing it. If you are not sure this is what you need please find out your engine model series number and contact our Customer-service.Thanks.

HAOSHUN Part Name:Fuel Injector || Part Number:ME215124 ME220255 093500-7500 093500-7510 || APPlication: FOR Mitsubishi 4D34T 4D34 Engine || 1. Please leave your physical address (home or office address) but do not leave your P.O. Box address and ensure that your address and contact information are correct. || 2.Please make sure it will fit your machine before purchasing it. If you are not sure this is what you need please find out your engine model series number and contact our Customer-service.Thanks.

$154.44

25 Mar 2025

CN: yahegochengeg

shsiyayh 4X Fuel Injector for Mitsubishi 4D34T 4D34 Engine ME215124 ME220255 093500-7500 093500-7510

shsiyayh Part Name:Fuel Injector || Part Number:ME215124 ME220255 093500-7500 093500-7510 || APPlication: Compatible with Mitsubishi 4D34T 4D34 Engine || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

shsiyayh Part Name:Fuel Injector || Part Number:ME215124 ME220255 093500-7500 093500-7510 || APPlication: Compatible with Mitsubishi 4D34T 4D34 Engine || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

$128.80

25 Mar 2025

0.1102[0.05] Pounds

CN: wuqingmeimei

IORSLLSA Fuel Injector ME215124 ME220255 093500-7500 093500-7510,Compatible for Mitsubishi 4D34T 4D34 Engine

IORSLLSA OEM NO. :ME220255 ME215124 093500-7500 0935007500 093500-7510 0935007510 || Fuel injectors provide better atomization, higher fuel efficiency, and more precise fuel injection || If you have any questions, you can consult me. We have a lot of car parts in our store. If you can't find the parts you need, you can contact me. || The fuel injector is sturdy, durable, easy to install, and has a long service life. Quality assurance, we will inspect the quality one by one before shipment || When ordering fuel injectors, please ensure that our part number matches yours. Please check our photos to ensure that the displayed parts are exactly the same as your car parts

IORSLLSA OEM NO. :ME220255 ME215124 093500-7500 0935007500 093500-7510 0935007510 || Fuel injectors provide better atomization, higher fuel efficiency, and more precise fuel injection || If you have any questions, you can consult me. We have a lot of car parts in our store. If you can't find the parts you need, you can contact me. || The fuel injector is sturdy, durable, easy to install, and has a long service life. Quality assurance, we will inspect the quality one by one before shipment || When ordering fuel injectors, please ensure that our part number matches yours. Please check our photos to ensure that the displayed parts are exactly the same as your car parts

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-07510

HOLDER & NOZZLE SE

ME215124

MITSUBISHI

Include in ##:

09350-07510

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935007510 MITSUBISHI

Nozzle

0934007680

First opm

17.65-18.63

First op

180-190

Second om

25.60-26.58

Second op

261-271

Torquen

24.5-34.3

Torque

2.5-3.5

Prelift

0.07-0.09

Max lift

0.23-0.28

Engine

CANTER 4D34T6

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-07510

ME215124

HOLDER & NOZZLE SE

0935007510

ME215124

MITSUBISHI

HOLDER & NOZZLE SE

Information:

Measuring Compression Pressure

Preparation for Inspection

Perform the following checks prior to inspection.(1) Make sure the engine oil, air cleaner, starter and battery are normal.(2) Make sure the engine is warm.Inspection

(1) Move the control lever to the top position.(2) Remove all glow plugs, then connect Compression Gauge Adapter (ST333060) and compression gauge to the cylinder whose compression is to be checked.

Compression gauge and adapter(3) Crank the engine using the starter until the needle of the compression gauge stops moving, then read the pressure indication.

Measuring compression pressure(4) If the measurement is lower than the specified limit, perform an overhaul.

(a) Measure the compression pressure of every cylinder. Measuring the compression pressure of two or three cylinders and simply assuming the compression pressures of the other cylinders is dangerous.(b) The compression pressure varies with the engine speed, so it is important to take all measurements with the same engine speed.

2Unit: MPa {kgf/cm} (psi) Take measurements with an engine speed of 240 min-1.

(a) It is important to measure compression pressures regularly and to keep track of changes in them.(b) During the engine's run-in period and after an overhaul, the compression pressures will increase slightly as the piston rings, valve seats, and other parts fit snugly in position. The Pressures will then decrease as parts wear.

Troubleshooting

Overview

Diesel-engine fault symptoms tend to have multiple causes, which influence each other. Consequently, it is often difficult to locate a fault based on the symptoms. Particular care is required when diagnosing faults related to the injection pump, injectors, and compression pressures since such faults may produce the same symptoms.For the above-mentioned reasons, the inspection sequences in the troubleshooting charts on the following pages start with items where the likelihood of a fault is greatest or with items that are easiest to inspect.Owing to their structure and combustion method, diesel engines exhibit the characteristics listed below. Familiarize yourself with these characteristics before performing troubleshooting operations.* Distinctive combustion noise (diesel knock) is emitted during normal operation.* Some black smoke is emitted during high-load operation.* Torque vibration is significant owing to the high compression pressure and high torque.* Slight hunting occurs during rapid deceleration.* Some white smoke is emitted immediately after startup when the engine is cold.

(a) The injection pump cannot be adjusted without a pump tester. Do not attempt to adjust or disassemble the injection pump during troubleshooting operations.(b) To check the combustion conditions in each cylinder, undo the cylinder's injection pipes one at a time (undoing an injection pipe stops injection in that cylinder) and compare the resulting decreases in engine speed. Retighten each injection pipe before undoing the next one.

Difficult Starting

(1) Items to Check

Before performing inspections, check for the following problems:* Clogged air cleaner element* Coagulation of engine oil* Inferior fuel* Low cranking speed(2) Inspection

Knocking

Diesel engines emit a distinctive knocking sound owing to their combustion method. This sound is normal unless it is excessive(1) Items to Check

Before performing inspections, check for the following problems:* Clogged air cleaner element* Inferior fuel(2) Inspection

Overheating

(1) Items to Check

Before performing inspections, check for the following

Preparation for Inspection

Perform the following checks prior to inspection.(1) Make sure the engine oil, air cleaner, starter and battery are normal.(2) Make sure the engine is warm.Inspection

(1) Move the control lever to the top position.(2) Remove all glow plugs, then connect Compression Gauge Adapter (ST333060) and compression gauge to the cylinder whose compression is to be checked.

Compression gauge and adapter(3) Crank the engine using the starter until the needle of the compression gauge stops moving, then read the pressure indication.

Measuring compression pressure(4) If the measurement is lower than the specified limit, perform an overhaul.

(a) Measure the compression pressure of every cylinder. Measuring the compression pressure of two or three cylinders and simply assuming the compression pressures of the other cylinders is dangerous.(b) The compression pressure varies with the engine speed, so it is important to take all measurements with the same engine speed.

2Unit: MPa {kgf/cm} (psi) Take measurements with an engine speed of 240 min-1.

(a) It is important to measure compression pressures regularly and to keep track of changes in them.(b) During the engine's run-in period and after an overhaul, the compression pressures will increase slightly as the piston rings, valve seats, and other parts fit snugly in position. The Pressures will then decrease as parts wear.

Troubleshooting

Overview

Diesel-engine fault symptoms tend to have multiple causes, which influence each other. Consequently, it is often difficult to locate a fault based on the symptoms. Particular care is required when diagnosing faults related to the injection pump, injectors, and compression pressures since such faults may produce the same symptoms.For the above-mentioned reasons, the inspection sequences in the troubleshooting charts on the following pages start with items where the likelihood of a fault is greatest or with items that are easiest to inspect.Owing to their structure and combustion method, diesel engines exhibit the characteristics listed below. Familiarize yourself with these characteristics before performing troubleshooting operations.* Distinctive combustion noise (diesel knock) is emitted during normal operation.* Some black smoke is emitted during high-load operation.* Torque vibration is significant owing to the high compression pressure and high torque.* Slight hunting occurs during rapid deceleration.* Some white smoke is emitted immediately after startup when the engine is cold.

(a) The injection pump cannot be adjusted without a pump tester. Do not attempt to adjust or disassemble the injection pump during troubleshooting operations.(b) To check the combustion conditions in each cylinder, undo the cylinder's injection pipes one at a time (undoing an injection pipe stops injection in that cylinder) and compare the resulting decreases in engine speed. Retighten each injection pipe before undoing the next one.

Difficult Starting

(1) Items to Check

Before performing inspections, check for the following problems:* Clogged air cleaner element* Coagulation of engine oil* Inferior fuel* Low cranking speed(2) Inspection

Knocking

Diesel engines emit a distinctive knocking sound owing to their combustion method. This sound is normal unless it is excessive(1) Items to Check

Before performing inspections, check for the following problems:* Clogged air cleaner element* Inferior fuel(2) Inspection

Overheating

(1) Items to Check

Before performing inspections, check for the following