Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL 4M40

Engine

4M40

Serial start-end

9512-

Info

Injector Nozzle

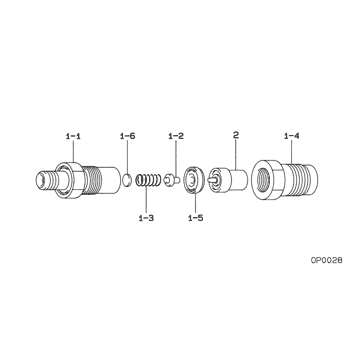

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-06430

HOLDER & NOZZLE SE

Include in ##:

09350-06430

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935006430 MITSUBISHI

Nozzle

0934005490

First opm

11.27-12.25

First op

115-125

Second om

-

Second op

-

Torquen

44.1-49.0

Torque

4.5-5.0

Prelift

-

Max lift

Engine

INDUSTRIAL 4M40

Information

Cross reference number

Part num

Firm num

Firm

Name

09350-06430

HOLDER & NOZZLE SE

Information:

Introduction

The problem that is identified below has a known solution. Use the solution that is identified below.Problem

The procedure for the Disassembly and Assembly needs to be updated to include the information below.Solution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Inspect the quill tubes and fuel injectors for cuts or marks at the mating surfaces.

Replace any quill tubes since the quill tubes are a one time use component. Replace the copper washer when replacing the fuel injector.

Follow the steps below for installing the quill tunes and fuel injectors.

Seat the injector by installing and torquing the injector hold down clamp bolt to 30 3 N m (22 2 lb ft).

Install the quill tube and tighten the quill nut between 15 N m (11 lb ft) to 20 N m (15 lb ft).

Apply a final torque of 30 3 N m (22 2 lb ft) to the injector hold down clamp bolt.

Apply a final torque between 50 N m (37 lb ft) to 55 N m (41 lb ft).

The problem that is identified below has a known solution. Use the solution that is identified below.Problem

The procedure for the Disassembly and Assembly needs to be updated to include the information below.Solution

Do not operate or work on this product unless you have read and understood the instruction and warnings in the relevant Operation and Maintenance Manuals and relevant service literature. Failure to follow the instructions or heed the warnings could result in injury or death. Proper care is your responsibility.

Inspect the quill tubes and fuel injectors for cuts or marks at the mating surfaces.

Replace any quill tubes since the quill tubes are a one time use component. Replace the copper washer when replacing the fuel injector.

Follow the steps below for installing the quill tunes and fuel injectors.

Seat the injector by installing and torquing the injector hold down clamp bolt to 30 3 N m (22 2 lb ft).

Install the quill tube and tighten the quill nut between 15 N m (11 lb ft) to 20 N m (15 lb ft).

Apply a final torque of 30 3 N m (22 2 lb ft) to the injector hold down clamp bolt.

Apply a final torque between 50 N m (37 lb ft) to 55 N m (41 lb ft).