Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL K4N-D

Engine

K4N-D

Serial start-end

9501-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$116.88

11 Feb 2025

CN: 湖北十堰贸联工贸有限公司

SLKJ 4pcs Fuel Injector 093500-6190 for Automotive Engine Fuel Supply System Parts

SLKJ NOTE: To avoid unnecessary returns, please make sure your part number matches the picture before purchasing. Or tell us your engine model photo and nameplate to reduce the error rate. || Features: high quality workmanship, long service life. || Usage: Easy to install, directly replace the old parts. || Packing: 4 x Fuel Injector || Warranty: 6 months warranty

SLKJ NOTE: To avoid unnecessary returns, please make sure your part number matches the picture before purchasing. Or tell us your engine model photo and nameplate to reduce the error rate. || Features: high quality workmanship, long service life. || Usage: Easy to install, directly replace the old parts. || Packing: 4 x Fuel Injector || Warranty: 6 months warranty

You can buy:

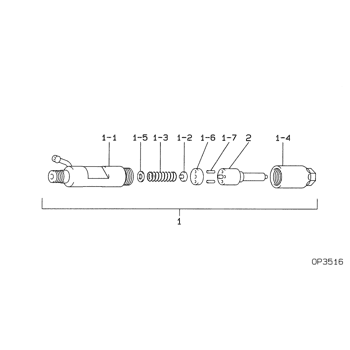

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-06190

HOLDER & NOZZLE SE

Include in ##:

09350-06190

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935006190 MITSUBISHI

Nozzle

0934005730

First opm

22.05-23.03

First op

225-235

Second om

-

Second op

-

Torquen

29.4-39.2

Torque

3.0-4.0

Prelift

-

Max lift

Engine

INDUSTRIAL K4N-D

Information

Cross reference number

Part num

Firm num

Firm

Name

09350-06190

HOLDER & NOZZLE SE

Information:

Introduction

The problem identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of faults codes with the DEF Pump, which can lead to an engine derate condition. Affected part numbers for the DEF pumps are:

473-2749 Diesel Exhaust Fluid Pump Gp

473-2750 Diesel Exhaust Fluid Pump Gp

466-8285 Diesel Exhaust Fluid Pump Gp

466-8286 Diesel Exhaust Fluid Pump GpThe codes can be:

Table 1

Event Codes

J1939 Code CDL Code Description

4334-16 E930 (2) Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2)

4334-18 E931 (2) Aftertreatment #1 SCR Dosing Re-agent Absolute Pressure : Low - moderate severity (2)

4374-5 E3118 (6) Aftertreatment #1 Diesel Exhaust Fluid Pump Motor Speed : Current Below Normal

5392-31 E1370 (2) Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime Caterpillar is investigating the root cause of these issues. To support the investigation, Caterpillar is requesting that the following steps are completed, documented, and recorded in SIMSi.Solution

Before starting any troubleshooting, download a Product Status Report (PSR) from the affected engine. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.Follow the appropriate troubleshooting steps for the displayed fault codes. Document the results of the troubleshooting tests in the relevant tables. Refer to Tables 2, 3, and 4.If Troubleshoot requests the Pump and Electronics Unit (PEU) to be replaced, conduct the following inspection before removal of the PEU.

Check the DEF for contamination, if the relevant troubleshooting procedure has not instructed you to do so. Refer to "System Operation Testing and Adjusting", Diesel Exhaust Fluid Quality - Test for the correct procedure.

Inspect the DEF tank cap, DEF header filter, DEF pump filter for any visible obstruction

Illustration 1 g06152768

(1) DEF line in

(2) DEF line out

(3) DEF line out let connection

(4) DEF line inlet connection

(5) Injector DEF line

Inspect and photograph both ends of the DEF fluid lines. If the ends of the lines are damaged or swollen, replace the DEF lines. Refer to "Disassembly and Assembly", Diesel Exhaust Fluid Lines - Remove and Install.At the end of the service take another PSR irrespective of outcome. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.If the troubleshooting steps have required a component to be changed, hold all replaced components for 30 days for a possible Parts Return Request (PRR). Make sure to include the closed work order paperwork.In every instance submit a SIMSi report, complete with TIB number M0079072, CPI number 359775 and submit through the CPI feedback tool within the SIMSi.

Detailed description of symptom experienced and under what conditions issue occurred

Product Status Report (PSR) before and after troubleshooting. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.

Completed Troubleshooting steps tables. Refer to Tables 2, 3, and 4.

Details of DEF tank cap, DEF header filter, DEF pump filter, visual inspection

Photos of DEF fluid lines

Details

The problem identified below does not have a permanent solution. Until a permanent solution is known, use the solution that is identified below.Problem

There have been instances of faults codes with the DEF Pump, which can lead to an engine derate condition. Affected part numbers for the DEF pumps are:

473-2749 Diesel Exhaust Fluid Pump Gp

473-2750 Diesel Exhaust Fluid Pump Gp

466-8285 Diesel Exhaust Fluid Pump Gp

466-8286 Diesel Exhaust Fluid Pump GpThe codes can be:

Table 1

Event Codes

J1939 Code CDL Code Description

4334-16 E930 (2) Aftertreatment #1 DEF #1 Pressure (absolute) : High - moderate severity (2)

4334-18 E931 (2) Aftertreatment #1 SCR Dosing Re-agent Absolute Pressure : Low - moderate severity (2)

4374-5 E3118 (6) Aftertreatment #1 Diesel Exhaust Fluid Pump Motor Speed : Current Below Normal

5392-31 E1370 (2) Aftertreatment Diesel Exhaust Fluid Dosing Unit Loss of Prime Caterpillar is investigating the root cause of these issues. To support the investigation, Caterpillar is requesting that the following steps are completed, documented, and recorded in SIMSi.Solution

Before starting any troubleshooting, download a Product Status Report (PSR) from the affected engine. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.Follow the appropriate troubleshooting steps for the displayed fault codes. Document the results of the troubleshooting tests in the relevant tables. Refer to Tables 2, 3, and 4.If Troubleshoot requests the Pump and Electronics Unit (PEU) to be replaced, conduct the following inspection before removal of the PEU.

Check the DEF for contamination, if the relevant troubleshooting procedure has not instructed you to do so. Refer to "System Operation Testing and Adjusting", Diesel Exhaust Fluid Quality - Test for the correct procedure.

Inspect the DEF tank cap, DEF header filter, DEF pump filter for any visible obstruction

Illustration 1 g06152768

(1) DEF line in

(2) DEF line out

(3) DEF line out let connection

(4) DEF line inlet connection

(5) Injector DEF line

Inspect and photograph both ends of the DEF fluid lines. If the ends of the lines are damaged or swollen, replace the DEF lines. Refer to "Disassembly and Assembly", Diesel Exhaust Fluid Lines - Remove and Install.At the end of the service take another PSR irrespective of outcome. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.If the troubleshooting steps have required a component to be changed, hold all replaced components for 30 days for a possible Parts Return Request (PRR). Make sure to include the closed work order paperwork.In every instance submit a SIMSi report, complete with TIB number M0079072, CPI number 359775 and submit through the CPI feedback tool within the SIMSi.

Detailed description of symptom experienced and under what conditions issue occurred

Product Status Report (PSR) before and after troubleshooting. Ensure that the PDF and the XML version of the PSR are downloaded, with the Histogram option selected in the Download List.

Completed Troubleshooting steps tables. Refer to Tables 2, 3, and 4.

Details of DEF tank cap, DEF header filter, DEF pump filter, visual inspection

Photos of DEF fluid lines

Details