Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

TRUCK D6A180

Engine

D6A180

Serial start-end

9508-

Info

Modification(Second opening pressure:221-231 297-307, September 1997). Refer to service bulletin TW97-09.

Injector Nozzle

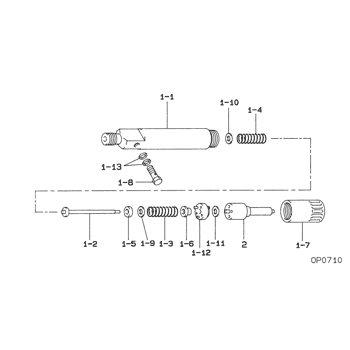

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Nozzle Specification:

Parts number

0935006130 VOLVO

Nozzle

0934006460

First opm

23.52-24.50

First op

240-250

Second om

21.65-22.63

Second op

221-231

Torquen

58.8-78.4

Torque

6.0-8.0

Prelift

0.108-0.128

Max lift

0.300-0.350

Engine

TRUCK D6A180

Information

Modification(Second opening pressure:221-231 -> 297-307, September 1997). Refer to service bulletin THZ97-01.

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-06130

HOLDER & NOZZLE SE

Information:

Note: In the U.S., burning fuel with greater than 15 ppm sulfur in model year 2007 and newer on-highway diesel engines is illegal and punishable with civil penalties.The two basic types of distillate diesel fuel are No. 2 diesel fuel and No. 1 diesel fuel. No. 2 diesel fuel is the most commonly available summer grade diesel fuel. No. 1 diesel fuel is a winter grade diesel fuel. During the winter months fuel suppliers will typically blend No. 1 and No. 2 diesel fuel in various percentages in order to meet the historical low ambient temperature cold-flow needs for a given area or region. No. 2 diesel fuel is a heavier diesel fuel than No. 1 diesel fuel. In cold weather, heavier fuels can cause problems with fuel filters, fuel lines, fuel tanks, and fuel storage. Heavier diesel fuels such as No. 2 diesel fuel can be used in diesel engines that operate in cold temperatures with an appropriate amount of a well proven pour point depressant additive. For more information on fuels which include blends of No. 1 and No. 2 diesel fuel, consult your fuel supplier.When you use No. 2 diesel fuel or other heavier fuels, some of the fuel's characteristics may interfere with successful cold weather operation. Additional information about the characteristics of diesel fuel is available. This information contains a discussion on the modification to the characteristics of diesel fuel. There are several possible methods that can be used to compensate for the fuel qualities that may interfere with cold weather operation. These methods include the use of starting aids, engine coolant heaters, fuel heaters, and de-icers. In addition, the manufacturer of the fuel can add cold flow improvers and/or blend No. 1 and No.2 diesel in various percentages.Not all areas of the world classify diesel fuel using the No. 1 and No. 2 nomenclature described above. But, the basic principles of using additives and/or blending fuels of different densities in order to help compensate for the fuel qualities that may interfere with cold weather operation are the same.Starting Aids

The use of a starting aid is a conventional method of assistance for cold starts in low temperature conditions. A variety of starting aids are available for Caterpillar engines. Follow the recommendations that are provided by the manufacturer of the starting aid. Refer to the foreword section in this Special Publication, "Aftermarket Products and Warranty" article.Engine Coolant Heaters

These heaters heat the engine coolant. The heated coolant flows through the cylinder block. The flow of heated coolant keeps the engine warm. A warm engine is easier to start in cold weather. Most coolant heaters use electrical power. A source of electricity is necessary for this type of heater. Other heaters that burn fuel are available as a source of heat. These heaters may be used in place of the electrical heaters.With either type of heater, starting aids and/or fuels with higher cetane numbers are less important because the engine is warm. Problems with fuel cloud point

The use of a starting aid is a conventional method of assistance for cold starts in low temperature conditions. A variety of starting aids are available for Caterpillar engines. Follow the recommendations that are provided by the manufacturer of the starting aid. Refer to the foreword section in this Special Publication, "Aftermarket Products and Warranty" article.Engine Coolant Heaters

These heaters heat the engine coolant. The heated coolant flows through the cylinder block. The flow of heated coolant keeps the engine warm. A warm engine is easier to start in cold weather. Most coolant heaters use electrical power. A source of electricity is necessary for this type of heater. Other heaters that burn fuel are available as a source of heat. These heaters may be used in place of the electrical heaters.With either type of heater, starting aids and/or fuels with higher cetane numbers are less important because the engine is warm. Problems with fuel cloud point