Rating:

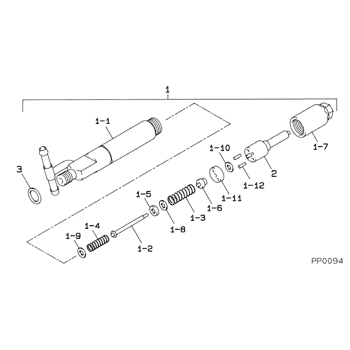

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

CANTER 4D33-4

Engine

4D33-4

Serial start-end

9502-

Info

Modification(Second opening pressure:200-210 -> 276-286, September 1997). Refer to service bulletin TW97-09.

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$319.79

16 Nov 2024

CN: QYWD

4X Fuel Injector ME012583 093500-6040 0935006040 for Mitsubishi 4D33

TUWODE Part Number: ME012583 093500-6040 || Item Type: Fuel Injector || Applicable Models: Fit for Mitsubishi 4D33 || Well-functioning fuel injectors ensure the correct air-fuel ratio, which is essential for minimizing harmful emissions. || Fuel is broken into fine droplets for optimal air mixing and enhanced combustion efficiency.

TUWODE Part Number: ME012583 093500-6040 || Item Type: Fuel Injector || Applicable Models: Fit for Mitsubishi 4D33 || Well-functioning fuel injectors ensure the correct air-fuel ratio, which is essential for minimizing harmful emissions. || Fuel is broken into fine droplets for optimal air mixing and enhanced combustion efficiency.

$319.79

16 Nov 2024

CN: QYWD

0935006040 093500-6040 ME012583 4X Fuel Injector for Mitsubishi 4D33

TUWODE Part Number: 935006040 093500-6040 || Item Type: Fuel Injector || Applicable Models: Fit for Mitsubishi 4D33 || Well-functioning fuel injectors ensure the correct air-fuel ratio, which is essential for minimizing harmful emissions. || Fuel is broken into fine droplets for optimal air mixing and enhanced combustion efficiency.

TUWODE Part Number: 935006040 093500-6040 || Item Type: Fuel Injector || Applicable Models: Fit for Mitsubishi 4D33 || Well-functioning fuel injectors ensure the correct air-fuel ratio, which is essential for minimizing harmful emissions. || Fuel is broken into fine droplets for optimal air mixing and enhanced combustion efficiency.

You can buy:

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-06040

HOLDER & NOZZLE SE

ME012583

MITSUBISHI

Include in ##:

09350-06040

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935006040 MITSUBISHI

Nozzle

0934006420

First opm

16.17-17.15

First op

165-175

Second om

19.60-20.58

Second op

200-210

Torquen

24.5-34.3

Torque

2.5-3.5

Prelift

0.070-0.090

Max lift

0.230-0.280

Engine

CANTER 4D33-4

Information

Modification(Second opening pressure:200-210 -> 276-286, September 1997). Refer to service bulletin THZ97-01.

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-06040

ME012583

HOLDER & NOZZLE SE

0935006040

ME012583

MITSUBISHI

HOLDER & NOZZLE SE

Information:

Regeneration

The process of particulate collection begins as soon as the engine is started and continues while the engine is operating. At low loads and low exhaust temperatures, PM accumulates in the filter and pressure drop across the filter increases. When exhaust conditions are optimal, the catalyst promotes oxidation between the particulate matter and either oxygen or nitrogen dioxide in the exhaust. This process is called regeneration whereby PM is burned off the substrate walls, resulting in a cleaner filter. The regeneration process is dependent upon exhaust temperature, engine load, exhaust composition, and fuel sulfur content. At a certain exhaust condition, the rate of oxidation eclipses the rate at which PM is being trapped by the filter. The temperature at this exhaust condition is commonly referred to as the regeneration temperature. The exhaust temperature does not have to be above regeneration temperature 100 percent of the time. The more time above regeneration temperature, the cleaner the filter will be. A cleaner filter results in lower backpressure. Operating above the regeneration temperature means that the filter will continuously regenerate and self clean. The requirement to operate the Cat DPF is to run above the regeneration temperature at least 30 percent of the time.REGENERATION IS THE SINGLE MOST IMPORTANT ASPECT OF THE CAT DPF OPERATION. The user must understand and plan for regeneration during the normal duty cycle of the engine. If a filter continues operation without regenerating, the filter will collect more and PM, restricting flow more and consequently adding more backpressure to the engine. If exhaust temperatures increase enough to begin regeneration, the large amount of PM on the filter may create a runaway regeneration. This condition is where the excess PM provides a large amount of fuel to burn. This condition then creates a large exothermic condition in the exhaust. This exothermic condition can be so great that the exothermic condition melts the ceramic substrate. The filter is then said to be burned out or cracked, and is unusable and irreparable. A burned out filter must be replacedOperation in No-Load Mode

A diesel engine should not be operated for long periods of time in a no-load mode. The no-load mode produces large amounts of particulate matter (PM) that can plug the Cat DPF due to low exhaust temperatures. Caterpillar recommends that no more than 12 cold starts, no-load mode of operation be done before running the engine at least 40 percent load

The process of particulate collection begins as soon as the engine is started and continues while the engine is operating. At low loads and low exhaust temperatures, PM accumulates in the filter and pressure drop across the filter increases. When exhaust conditions are optimal, the catalyst promotes oxidation between the particulate matter and either oxygen or nitrogen dioxide in the exhaust. This process is called regeneration whereby PM is burned off the substrate walls, resulting in a cleaner filter. The regeneration process is dependent upon exhaust temperature, engine load, exhaust composition, and fuel sulfur content. At a certain exhaust condition, the rate of oxidation eclipses the rate at which PM is being trapped by the filter. The temperature at this exhaust condition is commonly referred to as the regeneration temperature. The exhaust temperature does not have to be above regeneration temperature 100 percent of the time. The more time above regeneration temperature, the cleaner the filter will be. A cleaner filter results in lower backpressure. Operating above the regeneration temperature means that the filter will continuously regenerate and self clean. The requirement to operate the Cat DPF is to run above the regeneration temperature at least 30 percent of the time.REGENERATION IS THE SINGLE MOST IMPORTANT ASPECT OF THE CAT DPF OPERATION. The user must understand and plan for regeneration during the normal duty cycle of the engine. If a filter continues operation without regenerating, the filter will collect more and PM, restricting flow more and consequently adding more backpressure to the engine. If exhaust temperatures increase enough to begin regeneration, the large amount of PM on the filter may create a runaway regeneration. This condition is where the excess PM provides a large amount of fuel to burn. This condition then creates a large exothermic condition in the exhaust. This exothermic condition can be so great that the exothermic condition melts the ceramic substrate. The filter is then said to be burned out or cracked, and is unusable and irreparable. A burned out filter must be replacedOperation in No-Load Mode

A diesel engine should not be operated for long periods of time in a no-load mode. The no-load mode produces large amounts of particulate matter (PM) that can plug the Cat DPF due to low exhaust temperatures. Caterpillar recommends that no more than 12 cold starts, no-load mode of operation be done before running the engine at least 40 percent load