Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

CANTER E65X

Engine

E65X

Serial start-end

9307-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

$162.79

12 Sep 2024

CN: CAR REFINE

4PCS Fuel Injector Mechanism fits 093500-5710 0935005710 for Mitsubishi Engine 4M40

Podafu Item Type: Fuel Injector || Part Code: 093500-5710 || Applicable Models: Compatible with Mitsubishi Engine 4M40 || Provides consistent fuel delivery to ensure smooth engine operation. || Extends the engine's peak performance, thereby improving the vehicle's dependability.

Podafu Item Type: Fuel Injector || Part Code: 093500-5710 || Applicable Models: Compatible with Mitsubishi Engine 4M40 || Provides consistent fuel delivery to ensure smooth engine operation. || Extends the engine's peak performance, thereby improving the vehicle's dependability.

$165.00

19 Jul 2024

CN: BCXFORK

BCXFORK 4PCS Fuel Injector 093500-5710 0935005710 fits for Mitsubishi Engine 4M40

BCXFORK NOTE Before placing an order, please verify that your part number matches the one in the listing. Some Fuel Injectors may look similar. If you're unsure, you can leave us a message and provide a picture of your old fuel injector for verification. || Note: We can provide various engine parts. If you need any additional parts, please leave us a message with the list of items you need. || Manufacturer Warranty 1 Year || Part Number: 093500-5710 0935005710 || This item fits for Mitsubishi Engine 4M40

BCXFORK NOTE Before placing an order, please verify that your part number matches the one in the listing. Some Fuel Injectors may look similar. If you're unsure, you can leave us a message and provide a picture of your old fuel injector for verification. || Note: We can provide various engine parts. If you need any additional parts, please leave us a message with the list of items you need. || Manufacturer Warranty 1 Year || Part Number: 093500-5710 0935005710 || This item fits for Mitsubishi Engine 4M40

ME200205 093500-5710 4 Pcs Fuel Injector for Mitsubishi Engine 4M40 Canter FD501B

Thcbme Part Number: 093500-5710 || Application: For Mitsubishi Engine 4M40 Canter FD501B || Ideal replacement: Precision engineered to match specific vehicles || Ensure fit: To make sure this part fits your exact vehicle. || Ensure fit: To make sure this part fits your exact vehicle.

Thcbme Part Number: 093500-5710 || Application: For Mitsubishi Engine 4M40 Canter FD501B || Ideal replacement: Precision engineered to match specific vehicles || Ensure fit: To make sure this part fits your exact vehicle. || Ensure fit: To make sure this part fits your exact vehicle.

You can buy:

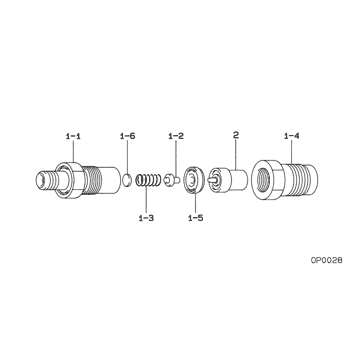

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-05710

HOLDER & NOZZLE SE

ME200205

MITSUBISHI

Include in ##:

09350-05710

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935005710 MITSUBISHI

Nozzle

0934005490

First opm

14.21-15.19

First op

145-155

Second om

-

Second op

-

Torquen

34.3-39.2

Torque

3.5-4.0

Prelift

-

Max lift

Engine

CANTER E65X

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-05710

ME200205

HOLDER & NOZZLE SE

0935005710

ME200205

MITSUBISHI

HOLDER & NOZZLE SE

Information:

Introduction

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.Certain engine components may need to be cleaned if soot is found in the system beyond the Diesel Particulate Filter (DPF). The contaminated components can be cleaned with hot water and soap by hand washing or in a parts washer. Do not use solvents. Special care must be taken with handling components of the Clean Gas Induction (CGI) cooler.Safety Section

Sulfuric Acid Burn Hazard, may cause serious personal injury.The clean gas induction cooler may contain a small amount of sulfuric acid. The use of fuel with sulfur levels greater than 15 ppm may increase the amount of sulfuric acid formed. The sulfuric acid may spill from the CGI cooler during service of the engine and may travel to other downstream components. The sulfuric acid will burn the eyes, skin and clothing on contact. Always wear the appropriate personal protective equipment (PPE) that is noted on a material safety data sheet (MSDS) for sulfuric acid. Always follow the directions for first aid that are noted on a material safety data sheet (MSDS) for sulfuric acid.

Hot engine components can cause injury from burns. Before performing maintenance on the engine, allow the engine and the components to cool.

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Caterpillar Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Caterpillar products.Dispose of all fluids according to local regulations and mandates.

Required Tools

Table 1

Part Number Part Description Qty

9N-6379 Air Cleaner Adapter Boot 1

4P-2706 Protection Cap 1 Cleaning Procedure

Start at the DPF outlet and inspect the components downstream of the CGI pipe until excessive soot is no longer found. If necessary, clean these components .

If soot is found at the entrance to the CGI cooler, remove the CGI cooler from the engine. Refer to Disassembly and Assembly, RENR9706, "Clean Gas Induction Cooler - Remove and Install", "Removal Procedure" in order to properly remove the CGI cooler.

After removing the CGI cooler, immediately submerge the CGI cooler into the hot soapy water.

Remove the 9N-6379 Air Cleaner Adapter Boot and the 4P-2706 Protection Cap from the ends of the CGI cooler.

Allow the water to circulate through the CGI cooler in order to dilute any sulfuric acid that may be present. Clean out the soot.

Continue to inspect the following components downstream of the CGI cooler until excessive soot is no longer found: the CGI mixing valve, the

Do not perform any procedure in this Special Instruction until you read this information and you understand this information.Certain engine components may need to be cleaned if soot is found in the system beyond the Diesel Particulate Filter (DPF). The contaminated components can be cleaned with hot water and soap by hand washing or in a parts washer. Do not use solvents. Special care must be taken with handling components of the Clean Gas Induction (CGI) cooler.Safety Section

Sulfuric Acid Burn Hazard, may cause serious personal injury.The clean gas induction cooler may contain a small amount of sulfuric acid. The use of fuel with sulfur levels greater than 15 ppm may increase the amount of sulfuric acid formed. The sulfuric acid may spill from the CGI cooler during service of the engine and may travel to other downstream components. The sulfuric acid will burn the eyes, skin and clothing on contact. Always wear the appropriate personal protective equipment (PPE) that is noted on a material safety data sheet (MSDS) for sulfuric acid. Always follow the directions for first aid that are noted on a material safety data sheet (MSDS) for sulfuric acid.

Hot engine components can cause injury from burns. Before performing maintenance on the engine, allow the engine and the components to cool.

Wear goggles, gloves, protective clothing, and a National Institute for Occupational Safety and Health (NIOSH) approved P95 or N95 half-face respirator when handling a used Diesel Particulate Filter or Catalytic Converter Muffler. Failure to do so could result in personal injury.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Caterpillar Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Caterpillar products.Dispose of all fluids according to local regulations and mandates.

Required Tools

Table 1

Part Number Part Description Qty

9N-6379 Air Cleaner Adapter Boot 1

4P-2706 Protection Cap 1 Cleaning Procedure

Start at the DPF outlet and inspect the components downstream of the CGI pipe until excessive soot is no longer found. If necessary, clean these components .

If soot is found at the entrance to the CGI cooler, remove the CGI cooler from the engine. Refer to Disassembly and Assembly, RENR9706, "Clean Gas Induction Cooler - Remove and Install", "Removal Procedure" in order to properly remove the CGI cooler.

After removing the CGI cooler, immediately submerge the CGI cooler into the hot soapy water.

Remove the 9N-6379 Air Cleaner Adapter Boot and the 4P-2706 Protection Cap from the ends of the CGI cooler.

Allow the water to circulate through the CGI cooler in order to dilute any sulfuric acid that may be present. Clean out the soot.

Continue to inspect the following components downstream of the CGI cooler until excessive soot is no longer found: the CGI mixing valve, the