Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL E3112

Engine

E3112

Serial start-end

9209-

Info

Injector Nozzle

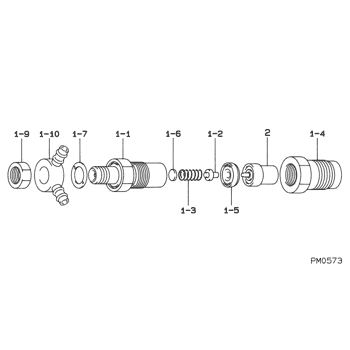

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-05640

HOLDER & NOZZLE SE

Include in ##:

09350-05640

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935005640 ISEKI

Nozzle

0934006200

First opm

11.76-12.74

First op

120-130

Second om

-

Second op

-

Torquen

34.3-39.2

Torque

3.5-4.0

Prelift

-

Max lift

Engine

agricultural machine E3112

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-05640

HOLDER & NOZZLE SE

Information:

Introduction

Do not perform any procedure in this Special Instruction until you have read this information and you understand this information.Remove the Fuse for the ARD Purge Air Pump

Note: The fuse must be removed before performing this procedure. If the fuse has not been removed, the fuse can be blown when the jumper harness is installed.

Remove the fuse for the ARD purge air pump. Consult the manufacturer of the chassis for the location of the fuse.Installing the Software

Note: The software must be updated before the iron is updated.

Update Cat ET to the ET2008A or a later version.

Download the current data for the truck.

The new software must be flashed before the engine is updated with the hardware. Damage will occur if the hardware is updated first.

Flash new software into the engine ECM. The software must be updated to 320-XXXX or later.

Illustration 1 g01443782

Set the configuration in Cat ET. Refer to Illustration 1.

Select "Emissions Parameters".

Select "ARD Fuel Nozzle Cleaner Configuration A".

Select "Nozzle Heater".Jumper Harness

Use the following procedure in order to complete the jumper harness.

Disconnect the electrical connector for the ARD purge air pump from the engine harness.

Check the engine harness connector for the ARD purge air pump. There are two possible configurations for the engine wiring:

If four wires are inserted into the engine harness connector for the ARD purge air pump, the engine wiring is already configured for the heated nozzle. Proceed to the ""Installing the Hardware"" section of this procedure. Note: This is effective with (S/N: SDP8270-UP) and (S/N: LEE6575-UP).

If three wires are inserted into the engine harness connector for the ARD purge air pump, the engine wiring is not configured for the heated nozzle. Continue with this procedure in order to configure the engine wiring for the heated nozzle.

Cut the three wires that are inserted into the engine harness connector for the ARD purge air pump. Be sure to cut the wires near the engine harness connector. Discard the electrical connector.

Crimp a new terminal onto the end of each wire.

Illustration 2 g01454961

Refer to Illustration 2 before you insert the wires into the 230-5008 Connector Plug As . Insert the pink wire into location 1. Insert the red wire into location 3. Insert the black wire into location 4. Insert the orange wire from the 317-0642 Wiring Kit into terminal 2.Note: The pink wire, the red wire, and the black wire are the wires from the engine harness. The orange wire is from the 317-0642 Wiring Kit .

Pull on each wire in order to verify that wire is fully inserted into the electrical connector.

Illustration 3 g01469937

Electrical schematic for the ARD purge air system

Illustration 4 g01469897

Electrical schematic for the heated nozzleInstalling the Hardware

Illustration 5 g01443304

(1) ARD purge air pump

Remove pump (1) and remove the associated components. Remove the lines for the purge air as well as the tee for the purge air. Install 9S-5518 Plug . Discard the pump and the components. Remove the cleaning port and the lines for the cleaning port.Note: Maintain cleanliness in order to prevent contamination.

There are two options for

Do not perform any procedure in this Special Instruction until you have read this information and you understand this information.Remove the Fuse for the ARD Purge Air Pump

Note: The fuse must be removed before performing this procedure. If the fuse has not been removed, the fuse can be blown when the jumper harness is installed.

Remove the fuse for the ARD purge air pump. Consult the manufacturer of the chassis for the location of the fuse.Installing the Software

Note: The software must be updated before the iron is updated.

Update Cat ET to the ET2008A or a later version.

Download the current data for the truck.

The new software must be flashed before the engine is updated with the hardware. Damage will occur if the hardware is updated first.

Flash new software into the engine ECM. The software must be updated to 320-XXXX or later.

Illustration 1 g01443782

Set the configuration in Cat ET. Refer to Illustration 1.

Select "Emissions Parameters".

Select "ARD Fuel Nozzle Cleaner Configuration A".

Select "Nozzle Heater".Jumper Harness

Use the following procedure in order to complete the jumper harness.

Disconnect the electrical connector for the ARD purge air pump from the engine harness.

Check the engine harness connector for the ARD purge air pump. There are two possible configurations for the engine wiring:

If four wires are inserted into the engine harness connector for the ARD purge air pump, the engine wiring is already configured for the heated nozzle. Proceed to the ""Installing the Hardware"" section of this procedure. Note: This is effective with (S/N: SDP8270-UP) and (S/N: LEE6575-UP).

If three wires are inserted into the engine harness connector for the ARD purge air pump, the engine wiring is not configured for the heated nozzle. Continue with this procedure in order to configure the engine wiring for the heated nozzle.

Cut the three wires that are inserted into the engine harness connector for the ARD purge air pump. Be sure to cut the wires near the engine harness connector. Discard the electrical connector.

Crimp a new terminal onto the end of each wire.

Illustration 2 g01454961

Refer to Illustration 2 before you insert the wires into the 230-5008 Connector Plug As . Insert the pink wire into location 1. Insert the red wire into location 3. Insert the black wire into location 4. Insert the orange wire from the 317-0642 Wiring Kit into terminal 2.Note: The pink wire, the red wire, and the black wire are the wires from the engine harness. The orange wire is from the 317-0642 Wiring Kit .

Pull on each wire in order to verify that wire is fully inserted into the electrical connector.

Illustration 3 g01469937

Electrical schematic for the ARD purge air system

Illustration 4 g01469897

Electrical schematic for the heated nozzleInstalling the Hardware

Illustration 5 g01443304

(1) ARD purge air pump

Remove pump (1) and remove the associated components. Remove the lines for the purge air as well as the tee for the purge air. Install 9S-5518 Plug . Discard the pump and the components. Remove the cleaning port and the lines for the cleaning port.Note: Maintain cleanliness in order to prevent contamination.

There are two options for