Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL E643

Engine

E643

Serial start-end

9107-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

shsiyayh 4X Fuel Injector for Perkins Engine Denso 093500-5170 0935005170

shsiyayh Part Name:Fuel Injector || Part Number:093500-5170 0935005170 || APPlication: Compatible with Perkins Engine Denso || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

shsiyayh Part Name:Fuel Injector || Part Number:093500-5170 0935005170 || APPlication: Compatible with Perkins Engine Denso || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

4 Pieces Compatible Fuel Injectors 131406340 0935005170 Compatible With

AQDCZSLS Compatibility: Designed specifically Compatible With engines, the 131406340 fuel injector ensures integration with your existing setup Compatible With reliable performance.Quality Construction: Manufactured by , these fuel injectors are built to withstand rigorous conditions, ensuring durability and longevity in various applications.Performance: Experience improved fuel atomization Compatible With enhanced combustion efficiency, contributing to better power delivery and reduced

AQDCZSLS Compatibility: Designed specifically Compatible With engines, the 131406340 fuel injector ensures integration with your existing setup Compatible With reliable performance.Quality Construction: Manufactured by , these fuel injectors are built to withstand rigorous conditions, ensuring durability and longevity in various applications.Performance: Experience improved fuel atomization Compatible With enhanced combustion efficiency, contributing to better power delivery and reduced

shsiyayh 1X Fuel Injector for Perkins Engine Denso 093500-5170 0935005170

shsiyayh Part Name:Fuel Injector || Part Number:093500-5170 0935005170 || APPlication: Compatible with Perkins Engine Denso || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

shsiyayh Part Name:Fuel Injector || Part Number:093500-5170 0935005170 || APPlication: Compatible with Perkins Engine Denso || 1.Please tell us of your engine model or a view of nameplate when order this item to lower the error rate.Thanks. || 2.There are no instructions included in this kit.it is recommended to install professionally.

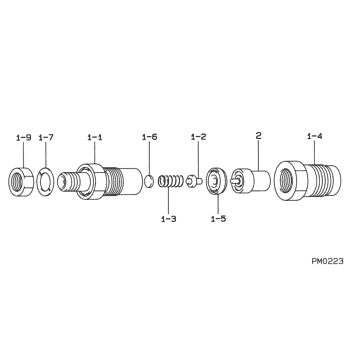

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-05170

HOLDER & NOZZLE SE

Include in ##:

09350-05170

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935005170 ISHIKAWAJIMA

Nozzle

0934005010

First opm

11.27-12.25

First op

115-125

Second om

-

Second op

-

Torquen

34.3-39.2

Torque

3.5-4.0

Prelift

-

Max lift

Engine

INDUSTRIAL E643

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-05170

HOLDER & NOZZLE SE

Information:

Introduction

This special instruction covers the procedure to install a Flow Through Diesel Particulate Filter on R1700G (S/N: SBR1-UP) Load Haul Dump machines equipped with Ventilation Reduction Package and the correct low sulphur fuel and low ash oil. This supplemental product support literature should be used with the appropriate Service Manual and the appropriate Parts Manual that is available for this standard machine.Note: This procedure cannot be used in Canadian provinces that require "CANMET "certification. This procedure will invalidate the existing "CANMET " approval for an engine.Read the entire Special Instruction. Understand the information before you perform any procedures. Understand the information before you order any parts.ReferenceDisassembly & Assembly Supplement, KENR6253, "R1700G Load Haul Dump C11 Engine Supplement".ReferenceSpecial Instruction, REHS5841, "Procedure to Install the Ventilation Reduction Package on R1700G Load Haul Dump Machines".Safety Section

Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools in order to perform these functions properly.Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive.Ensure that all personnel are safe when using a tool, procedure, work method, or operating technique not recommended by Caterpillar. Ensure that the product will not be damaged or the product made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact the skin.

Personal injury or death can result from machine articulation or movement. Machine frames can move and a person can be crushed. Connect the steering frame lock between the front and rear frames before working on the machine.Before operating the machine, place the steering frame lock in the stored position.Failure to place the steering frame lock into the stored position before operating can result in loss of steering.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Parts Required

Table 1

Required Parts (1) (2)

QTY New Part Number Description

1 395-0215 Diesel Particulate Filter Gp

1 349-8603 Film (1)

1 349-8604 Film (2)

1 350-0684 Film

1 1W-3342 V Band Clamp

1 186-9686 Gasket

2 8N-2729 Metal Seal Ring

1 9N-1941 V Band Clamp

( 1 ) 349-8603 is ANSI film (US & CANADA).

( 2 ) 349-8604 is ISO film (REST

This special instruction covers the procedure to install a Flow Through Diesel Particulate Filter on R1700G (S/N: SBR1-UP) Load Haul Dump machines equipped with Ventilation Reduction Package and the correct low sulphur fuel and low ash oil. This supplemental product support literature should be used with the appropriate Service Manual and the appropriate Parts Manual that is available for this standard machine.Note: This procedure cannot be used in Canadian provinces that require "CANMET "certification. This procedure will invalidate the existing "CANMET " approval for an engine.Read the entire Special Instruction. Understand the information before you perform any procedures. Understand the information before you order any parts.ReferenceDisassembly & Assembly Supplement, KENR6253, "R1700G Load Haul Dump C11 Engine Supplement".ReferenceSpecial Instruction, REHS5841, "Procedure to Install the Ventilation Reduction Package on R1700G Load Haul Dump Machines".Safety Section

Work safely. Most accidents that involve product operation, maintenance, and repair are caused by failure to observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous situations before an accident occurs. A person must be alert to potential hazards. This person should also have the necessary training, skills, and tools in order to perform these functions properly.Safety precautions and warnings are provided in this instruction and on the product. If these hazard warnings are not heeded, bodily injury or death could occur to you or to other persons. Caterpillar cannot anticipate every possible circumstance that might involve a potential hazard. Therefore, the warnings in this publication and the warnings that are on the product are not all inclusive.Ensure that all personnel are safe when using a tool, procedure, work method, or operating technique not recommended by Caterpillar. Ensure that the product will not be damaged or the product made unsafe by the operation, lubrication, maintenance, or the repair procedures that are used.

Hot oil and hot components can cause personal injury. Do not allow hot oil or hot components to contact the skin.

Personal injury or death can result from machine articulation or movement. Machine frames can move and a person can be crushed. Connect the steering frame lock between the front and rear frames before working on the machine.Before operating the machine, place the steering frame lock in the stored position.Failure to place the steering frame lock into the stored position before operating can result in loss of steering.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Parts Required

Table 1

Required Parts (1) (2)

QTY New Part Number Description

1 395-0215 Diesel Particulate Filter Gp

1 349-8603 Film (1)

1 349-8604 Film (2)

1 350-0684 Film

1 1W-3342 V Band Clamp

1 186-9686 Gasket

2 8N-2729 Metal Seal Ring

1 9N-1941 V Band Clamp

( 1 ) 349-8603 is ANSI film (US & CANADA).

( 2 ) 349-8604 is ISO film (REST