Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL 4DQ

Engine

4DQ

Serial start-end

9005-

Info

Injector Nozzle

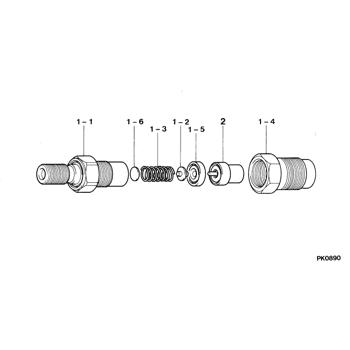

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-04750

HOLDER & NOZZLE SE

Include in ##:

09350-04750

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935004750 MITSUBISHI

Nozzle

0934005210

First opm

11.76-12.74

First op

120-130

Second om

-

Second op

-

Torquen

34.3-39.2

Torque

3.5-4.0

Prelift

-

Max lift

Engine

agricultural machine 4DQ

Information

Cross reference number

Part num

Firm num

Firm

Name

09350-04750

HOLDER & NOZZLE SE

Information:

Introduction

The following special instructions must be used to test for a crack in the Diesel Particulate Filter (DPF). Do not perform any procedure that is outlined in this Special Instruction until you have read and understand the information that is contained in this document.Required Tools

Table 1

Required Tools

Tool Part Number Part Description Qty

A 380-5200 Tool Kit 1

B 366-7782 Attenuator 1 Testing Procedure

Perform a "Manual Diesel Particulate Filter Regeneration" using the electronic service tool.

After the manual DPF regeneration is complete, operate the engine at 1800 rpm for a MINIMUM of 20 minutes to stabilize the DPF temperatures.Note: The engine must maintain a steady speed for the entire duration of the test.

Hot engine components can cause injury from burns. Before performing maintenance on the engine, allow the engine and the components to cool.

Illustration 1 g02597531

Typical example (1) DPF Outlet Cap (2) Filter Paper (3) Hose Assembly (4) Air Pump

Illustration 2 g03655197

Typical example

Stop the engine. Disconnect harness assembly from both soot antennae. Remove outlet soot antenna (5). Refer to

The following special instructions must be used to test for a crack in the Diesel Particulate Filter (DPF). Do not perform any procedure that is outlined in this Special Instruction until you have read and understand the information that is contained in this document.Required Tools

Table 1

Required Tools

Tool Part Number Part Description Qty

A 380-5200 Tool Kit 1

B 366-7782 Attenuator 1 Testing Procedure

Perform a "Manual Diesel Particulate Filter Regeneration" using the electronic service tool.

After the manual DPF regeneration is complete, operate the engine at 1800 rpm for a MINIMUM of 20 minutes to stabilize the DPF temperatures.Note: The engine must maintain a steady speed for the entire duration of the test.

Hot engine components can cause injury from burns. Before performing maintenance on the engine, allow the engine and the components to cool.

Illustration 1 g02597531

Typical example (1) DPF Outlet Cap (2) Filter Paper (3) Hose Assembly (4) Air Pump

Illustration 2 g03655197

Typical example

Stop the engine. Disconnect harness assembly from both soot antennae. Remove outlet soot antenna (5). Refer to