Rating:

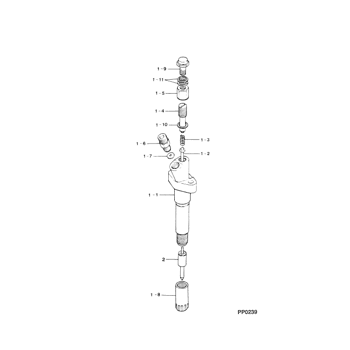

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL 6D16

Engine

6D16

Serial start-end

8912-

Info

Injector Nozzle

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-04520

HOLDER & NOZZLE SE

Include in ##:

09350-04520

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935004520 MITSUBISHI

Nozzle

0934002360

First opm

22.05-22.83

First op

225-233

Second om

-

Second op

-

Torquen

58.8-78.4

Torque

6.0-8.0

Prelift

-

Max lift

Engine

INDUSTRIAL 6D16

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-04520

HOLDER & NOZZLE SE

Information:

Introduction

This Special Instruction contains the strap torquing procedure for the straps on the DEF tank.Read the entire Special Instruction. Understand the information before you perform any procedures. Strap Torquing Procedure

Illustration 1 g03354750

(1) Strap (2) Nut

Install strap (1) and torque nut (2) .Torque for nut (2) ... 11 1 N m (97 9 lb in)Note: If the strap has a hook or other non-adjustable fastener on one end, only the adjustment end is torqued during installation.Note: If both ends of the strap have adjustable fasteners, both ends should be torqued only once. Do not go back and forth when applying assembly torque. Torque the first side to specification, then ensure that the torque on the second side is at specifications. Do not go back and retorque the first side.

This Special Instruction contains the strap torquing procedure for the straps on the DEF tank.Read the entire Special Instruction. Understand the information before you perform any procedures. Strap Torquing Procedure

Illustration 1 g03354750

(1) Strap (2) Nut

Install strap (1) and torque nut (2) .Torque for nut (2) ... 11 1 N m (97 9 lb in)Note: If the strap has a hook or other non-adjustable fastener on one end, only the adjustment end is torqued during installation.Note: If both ends of the strap have adjustable fasteners, both ends should be torqued only once. Do not go back and forth when applying assembly torque. Torque the first side to specification, then ensure that the torque on the second side is at specifications. Do not go back and retorque the first side.