Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL L3

Engine

L3

Serial start-end

8704-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

COPACHI 3pcs Fuel Injector Replace mm435-94101 OE 0935003840 Compatible with Mitsubishi L2E L3E S3L S4L S3L2 S4L2 S4S Diesel Engine, s3l injector, fuel injectors for a s3l2

COPACHI PART NAME: Fuel Injector. OE PART NUMBER: mm435-94101 0935003840, 093500-3840, MM435-94101, MM435-94101,s3l injector || CONFIRM YOUR PARTS: Please be sure to confirm the PART NUMBER/MAKE/MODEL/YEAR before purchasing to make sure the part is suitable for your vehicle || QUALITY CONTROL: We will conduct strict quality inspection and testing before shipment, and package the items well to ensure that the products are delivered to you in good condition || PRODUCT FEATURES: High-quality materials, OE standards, professional manufacturing, long service life, easy installation and operation, safe and reliable, stable performance, effective operation, direct replacement || AFTER-SALES SERVICE: If you encounter any problems during the use of the product, please send us the detailed specific instructions or pictures first, and we can provide corresponding services according to your needs

COPACHI PART NAME: Fuel Injector. OE PART NUMBER: mm435-94101 0935003840, 093500-3840, MM435-94101, MM435-94101,s3l injector || CONFIRM YOUR PARTS: Please be sure to confirm the PART NUMBER/MAKE/MODEL/YEAR before purchasing to make sure the part is suitable for your vehicle || QUALITY CONTROL: We will conduct strict quality inspection and testing before shipment, and package the items well to ensure that the products are delivered to you in good condition || PRODUCT FEATURES: High-quality materials, OE standards, professional manufacturing, long service life, easy installation and operation, safe and reliable, stable performance, effective operation, direct replacement || AFTER-SALES SERVICE: If you encounter any problems during the use of the product, please send us the detailed specific instructions or pictures first, and we can provide corresponding services according to your needs

Bulubiu 4PCS Fuel Injector 729004-53101 Fit for Yanmar 4 CYL 3TNV84 3TNV88 4TNV84 4TNV88 diesel Engine aftermarket part Replace OE 093500-3840 72900453101

Bulubiu 【OE part number】Fuel Inject 729004-53101、093500-3840、72900453101 || 【Product Features】 Exquisite manufacturing, complex design, large dynamic flow range, anti clogging and anti pollution capabilities, good atomization performance, precise control of fuel injection efficiency and quantity, improving combustion efficiency and reducing emissions || 【Material Characteristics】 This product is made of metal, plastic, and rubber, endowing the syringe with corrosion resistance, sealing performance, and the ability to adapt to different environments, ensuring the reliability and durability of the syringe || 【Precautions】 Before purchasing, please carefully check the OE number and model in the title or product description, and confirm whether the accessories match your car to avoid shopping inconvenience || 【Friendly Reminder】 Please do not provide a post office box/APO/FPO address, otherwise we will not be able to arrange delivery personnel

Bulubiu 【OE part number】Fuel Inject 729004-53101、093500-3840、72900453101 || 【Product Features】 Exquisite manufacturing, complex design, large dynamic flow range, anti clogging and anti pollution capabilities, good atomization performance, precise control of fuel injection efficiency and quantity, improving combustion efficiency and reducing emissions || 【Material Characteristics】 This product is made of metal, plastic, and rubber, endowing the syringe with corrosion resistance, sealing performance, and the ability to adapt to different environments, ensuring the reliability and durability of the syringe || 【Precautions】 Before purchasing, please carefully check the OE number and model in the title or product description, and confirm whether the accessories match your car to avoid shopping inconvenience || 【Friendly Reminder】 Please do not provide a post office box/APO/FPO address, otherwise we will not be able to arrange delivery personnel

6pcs 093500-3840 093100-3840 093400-5060 MM43594101 Engine Injectors Fuel for M1TSUBISH1 S4L-31/S6S with 3 Months

Generic Is customized: Yes || Origin: Mainland China || Certification: None || For DIY supplies: ELECTRICAL || Model number: for M1TSUBISH1 S4L-31 S6S Engine

Generic Is customized: Yes || Origin: Mainland China || Certification: None || For DIY supplies: ELECTRICAL || Model number: for M1TSUBISH1 S4L-31 S6S Engine

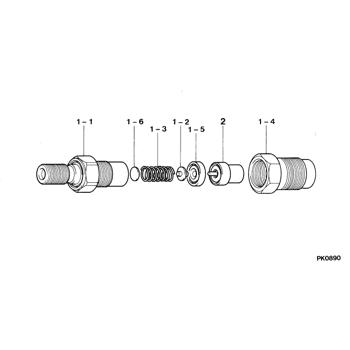

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-03840

HOLDER & NOZZLE SE

Include in ##:

09350-03840

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935003840 MITSUBISHI

Nozzle

0934005060

First opm

14.21-14.99

First op

145-153

Second om

-

Second op

-

Torquen

34.3-39.2

Torque

3.5-4.0

Prelift

-

Max lift

Engine

INDUSTRIAL L3

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-03840

HOLDER & NOZZLE SE

Information:

Start By:a. remove oil pump1. Check the connecting rods and caps for their identification and location. 2. Turn the crankshaft until the connecting rod caps are in the position shown.3. Remove bolts (1) and the and the bearing caps. Remove the lower half of the bearing from the cap.4. Push the connecting rod away from the crankshaft. Remove the upper half of the bearing from the connecting rod. Install the bearings dry when the clearance checks are made. Put clean engine oil on the bearings for final assembly.5. Install the upper half of the bearing in the connecting rod.6. Pull the connecting rod slowly on to the crankshaft.7. Install the lower half of the bearing in the cap. Be sure the tabs in the back of bearings are in the tab grooves of the connecting rod and cap.The serviceman must be very careful to use Plastigage, tool (A) correctly. The following points must be remembered:... Make sure that the backs of the bearings and the bores are clean and dry.... Make sure that the bearing locking tabs are properly seated in their slots.... The crankshaft must be free of oil where the Plastigage touches it.... Put a piece of Plastigage (A) on the crown of the bearing half that is in the cap. Do not allow the Plastigage to extend over the edge of the bearing.... Install the bearing cap using the correct torque-turn specifications. Do not use an impact wrench. Be careful not to dislodge the bearing when the cap is installed.... Do not turn the crankshaft with the Plastigage installed.... Carefully remove the cap but do not remove the Plastigage. Measure the width of the Plastigage while it is in the bearing cap or on the crankshaft journal. Do this by using the correct scale on the package. Record the measurements.... Remove the Plastigage before reinstalling the cap.When using Plastigage, the readings can sometimes be unclear. For example, all parts of the Plastigage are not the same width. Measure the major widths to make sure that they are within the specification range. Also, experience has shown that when checking clearances tighter than 0.10 mm (.004") the readings may be low by 0.013 to 0.025 mm (.0005 to .0010"). Out-of-round journals can give faulty readings. Also, journal taper may be indicated when one end of the Plastigage is wider that the other.For complete details concerning measuring bearing clearances, see Engine Bearings And Crankshafts, Form No. SEBD0531. 8. Use Plastigage (A) to check the bearing clearance.9. Put Plastigage (A) on the bearing.10. Put 2P2506 Thread Lubricant on the threads of the rod bolts. Be sure the cylinder numbers on the rod cap and rod are the same and are on the same side of connecting rod. Numbers are on the same side of the rod and cap as are the bearing tab slots. If new rods are installed, put the cylinder number on the rod and cap. Do not turn the crankshaft when Plastigage (A) is in position.