Rating:

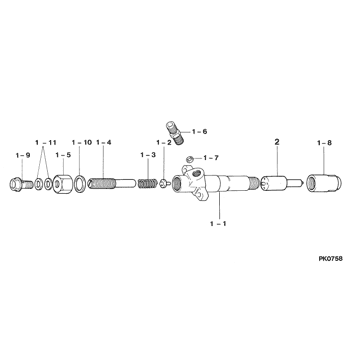

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

TRUCK H06C-TE

Engine

H06C-TE

Serial start-end

8605-

Info

Injector Nozzle

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Nozzle Specification:

Parts number

0935003500 HINO

Nozzle

0934002002

First opm

19.60-20.38

First op

200-208

Second om

-

Second op

-

Torquen

58.8-78.4

Torque

6.0-8.0

Prelift

-

Max lift

Engine

TRUCK H06C-TE

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-03500

HOLDER & NOZZLE SE

Information:

Introduction

Do not perform any procedure in this Special Instruction until you read this information and you understand this information. This Special Instruction is intended for the installation of the 257-4183 Injector Wiring Harness Kit . The 257-4183 Injector Wiring Harness Kit can be used to repair fuel injector connectors.

Table 1

Required Tools

Tool Part Number Part Name Qty

A 9S-9150 Terminal Crimp Tool As 1

B 9U-6070 Heat Gun Gp 1 Removal of a Faulty Connector from the Wire Harness

The following steps can be used in order to remove a faulty connector for an injector on the wire harness that is located under the valve mechanism cover.

Identify the connector that needs to be replaced. Wiring for the injector solenoid is not sensitive to polarity.

Illustration 1 g01111254

Connector that is cut from the wire harness

Cut wire (1) at a distance of 70 mm (2.8 inch) from the rear surface of the connector.

Cut wire (2) at a distance of 65 mm (2.6 inch) from the rear surface of the connector.

Illustration 2 g01111314

(3) Wire from the harness for side (B) on the connector (4) Wire from the harness for side (A) on the connectorNote: The wires on the old connector are cut to length so that the wires on the wire harness will match up to the new connector. Cutting the wires to the proper length will aid in matching the harness wires to the wires on the new connector.

Discard the old connector.Installation of a New Connector

The following steps can be used in order to install a new connector for an injector on the wire harness that is located under the valve mechanism cover.

Use Tool (A) in order to remove 5 mm (0.2 inch) of the plastic from wires (3) and (4) .

Illustration 3 g01111333

Connecting the connector to the wire harness (A) Side (A) of the new connector (B) Side (B) of the new connector (3) Wire from the harness for side (B) on the new connector (4) Wire from the harness for side (A) on the new connector (5) Heat shrink tubes (6) Butt splice on the wire that is on side (A) of the new connector (7) Butt splice on the wire that is on side (B) of the new connector

Use heat shrink tubes (5) from the 257-4183 Injector Wiring Harness Kit . Slide the heat shrink tubes toward the connector in order to expose the butt splices.

Insert wire (4) into butt splice (6) .

Insert wire (3) into butt splice (7) .

Do not perform any procedure in this Special Instruction until you read this information and you understand this information. This Special Instruction is intended for the installation of the 257-4183 Injector Wiring Harness Kit . The 257-4183 Injector Wiring Harness Kit can be used to repair fuel injector connectors.

Table 1

Required Tools

Tool Part Number Part Name Qty

A 9S-9150 Terminal Crimp Tool As 1

B 9U-6070 Heat Gun Gp 1 Removal of a Faulty Connector from the Wire Harness

The following steps can be used in order to remove a faulty connector for an injector on the wire harness that is located under the valve mechanism cover.

Identify the connector that needs to be replaced. Wiring for the injector solenoid is not sensitive to polarity.

Illustration 1 g01111254

Connector that is cut from the wire harness

Cut wire (1) at a distance of 70 mm (2.8 inch) from the rear surface of the connector.

Cut wire (2) at a distance of 65 mm (2.6 inch) from the rear surface of the connector.

Illustration 2 g01111314

(3) Wire from the harness for side (B) on the connector (4) Wire from the harness for side (A) on the connectorNote: The wires on the old connector are cut to length so that the wires on the wire harness will match up to the new connector. Cutting the wires to the proper length will aid in matching the harness wires to the wires on the new connector.

Discard the old connector.Installation of a New Connector

The following steps can be used in order to install a new connector for an injector on the wire harness that is located under the valve mechanism cover.

Use Tool (A) in order to remove 5 mm (0.2 inch) of the plastic from wires (3) and (4) .

Illustration 3 g01111333

Connecting the connector to the wire harness (A) Side (A) of the new connector (B) Side (B) of the new connector (3) Wire from the harness for side (B) on the new connector (4) Wire from the harness for side (A) on the new connector (5) Heat shrink tubes (6) Butt splice on the wire that is on side (A) of the new connector (7) Butt splice on the wire that is on side (B) of the new connector

Use heat shrink tubes (5) from the 257-4183 Injector Wiring Harness Kit . Slide the heat shrink tubes toward the connector in order to expose the butt splices.

Insert wire (4) into butt splice (6) .

Insert wire (3) into butt splice (7) .