Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

LANCER/MIRAGE 4D68

Engine

4D68

Serial start-end

8712-

Info

Injector Nozzle

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

4 PCS for Denso Fuel Injector 093500-3460 MD080288 for Mitsubishi Engine 4D65T 4D56

FORWEGPAD Part Number: 093500-3460, 093100-3460, 093400-5370, 093500 3460, 093100 3460, 093400 5370, 0935003460, 0931003460, 0934005370, MD080288 || Application: Fit for Mitsubishi Engine: 4D65T, 4D56

FORWEGPAD Part Number: 093500-3460, 093100-3460, 093400-5370, 093500 3460, 093100 3460, 093400 5370, 0935003460, 0931003460, 0934005370, MD080288 || Application: Fit for Mitsubishi Engine: 4D65T, 4D56

$116.88

21 Jan 2025

CN: 湖北十堰贸联工贸有限公司

SLKJ 4pcs Injectors 093500-3460 for Auto Parts Engine Fuel System

SLKJ NOTE: To avoid unnecessary returns, please make sure your part number matches the picture before purchasing. If you are not sure, you can message us and provide a photo of your old injector for inspection. || Features: high quality workmanship, long service life. || Usage: Easy to install, directly replace the old parts. || Packing: 4 x Fuel Injector || Warranty: 6 months warranty

SLKJ NOTE: To avoid unnecessary returns, please make sure your part number matches the picture before purchasing. If you are not sure, you can message us and provide a photo of your old injector for inspection. || Features: high quality workmanship, long service life. || Usage: Easy to install, directly replace the old parts. || Packing: 4 x Fuel Injector || Warranty: 6 months warranty

$188.25

27 Dec 2024

CN: Starhycfa

6Pcs Fuel Injection 093500-3460 Compatible with Mitsubishi 4D65T 4D56

Starhycfa Product name:Fuel Injection || Part Number:093500-3460 || APPlication:Compatible with Mitsubishi 4D65T 4D56 || 1.Please carefully compare the pictures or OE numbers to match your original parts before purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours before order. To Avoid placing wrong orders and wasting your precious time.

Starhycfa Product name:Fuel Injection || Part Number:093500-3460 || APPlication:Compatible with Mitsubishi 4D65T 4D56 || 1.Please carefully compare the pictures or OE numbers to match your original parts before purchasing the product. || 2.Please make sure that the model number, part number and photo is the same as yours before order. To Avoid placing wrong orders and wasting your precious time.

You can buy:

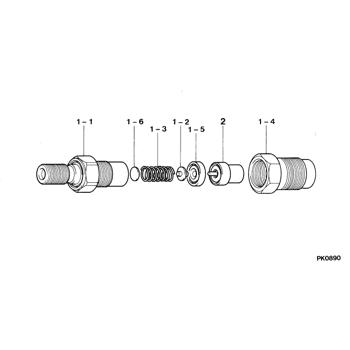

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-03460

HOLDER & NOZZLE SE

KCA

MD080288

MITSUBISHI

Include in ##:

09350-03460

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935003460 MITSUBISHI

Nozzle

0934005370

First opm

12.25-13.03

First op

125-133

Second om

-

Second op

-

Torquen

34.3-39.2

Torque

3.5-4.0

Prelift

-

Max lift

Engine

LANCER/MIRAGE 4D68

Information

Cross reference number

Part num

Firm num

Firm

Name

09350-03460

MD080288

HOLDER & NOZZLE SE

0935003460

MD080288

MITSUBISHI

HOLDER & NOZZLE SE

Information:

Start By:a. disassemble governorb. remove fuel injection pumps 1. Remove rack (1) from the fuel pump housing. 2. Remove six lifters (2) from the fuel pump housing. Put identification marks on the lifters for installation purposes. 3. Remove camshaft (3) from the fuel pump housing. It may be necessary to use a soft hammer to push the camshaft out of the governor end of the fuel pump housing. 4. Remove races (4) and bearing (5) from the camshaft. Remove ring (6) if necessary. 5. Remove rack bearing (7) from both ends of the housing and dowel (8) if necessary. 6. Use tooling (A), and remove three camshaft bearings (9). 7. Remove the bolts, cover (10) and the gasket. 8. Remove pins (12), the seal and dowels (11) if necessary. Pins (12) must be pushed from the inside out.Assemble Fuel Injection Pump Housing

1. Clean and inspect all parts. Make a replacement of all parts that are worn or damaged. 2. Lubricate the seal with clean engine oil, and install pin (12). Pin (12) must protrude into the pump bore 2.15 .05 mm (.085 .002 in.).3. Install dowel (11) so that it protrudes into the pump bore 1.93 0.05 mm (.076 .002 in.). 4. Install the gasket, cover (10) and the bolts. 5. Install the rack bearing with tooling (B). Install the bearing until the driver comes in contact with the plate. The bearing should be installed to a depth of 83.0 0.5 mm (3.27 .02 in.) from the fuel pump mounting face. 6. Measure rack bearing (7). Dimension (X) must be 11.178 0.05 mm (.4400 .002 in.). Diameter (W) must be 12.767 0.058 mm (.5026 .0022 in.). 7. Install dowel (8). Dowel (8) must protrude 6.0 0.5 mm (.24 .02 in.) from the fuel pump housing face.8. Install the rear rack bearing with tooling (C) to a depth of 7.16 0.13 mm (.282 .005 in.) below the fuel pump housing surface. The inside diameter of the rear rack bearing must be 12.746 0.045 mm (.5018 .0017 in.). 9. Use tooling (D), and install three camshaft bearings (9). Oil holes (13) in the camshaft bearings must be positioned 30° 3° above the horizontal centerline toward the engine side of the fuel pump housing. The outer bearings must be installed 1.0 0.5 mm (0.04 0.02 in.) below the surface marked (Z). The inner bearing must be installed 218.0 0.3 mm (8.58 .012 in.) below the front surface (Y). Diameter (XX) must be 68.339 0.038 mm (2.6905 .0015 in.) after assembly. 10. Install ring (6) races (4) and bearing (5) on the camshaft. 11. Lubricate cam bearings (9) and the camshaft bearing journals with clean engine oil.12. Install camshaft (3) into the fuel pump housing.

The notch in the lifter must be in line with the dowel in the lifter bore. The lifter must slide up and down freely in

1. Clean and inspect all parts. Make a replacement of all parts that are worn or damaged. 2. Lubricate the seal with clean engine oil, and install pin (12). Pin (12) must protrude into the pump bore 2.15 .05 mm (.085 .002 in.).3. Install dowel (11) so that it protrudes into the pump bore 1.93 0.05 mm (.076 .002 in.). 4. Install the gasket, cover (10) and the bolts. 5. Install the rack bearing with tooling (B). Install the bearing until the driver comes in contact with the plate. The bearing should be installed to a depth of 83.0 0.5 mm (3.27 .02 in.) from the fuel pump mounting face. 6. Measure rack bearing (7). Dimension (X) must be 11.178 0.05 mm (.4400 .002 in.). Diameter (W) must be 12.767 0.058 mm (.5026 .0022 in.). 7. Install dowel (8). Dowel (8) must protrude 6.0 0.5 mm (.24 .02 in.) from the fuel pump housing face.8. Install the rear rack bearing with tooling (C) to a depth of 7.16 0.13 mm (.282 .005 in.) below the fuel pump housing surface. The inside diameter of the rear rack bearing must be 12.746 0.045 mm (.5018 .0017 in.). 9. Use tooling (D), and install three camshaft bearings (9). Oil holes (13) in the camshaft bearings must be positioned 30° 3° above the horizontal centerline toward the engine side of the fuel pump housing. The outer bearings must be installed 1.0 0.5 mm (0.04 0.02 in.) below the surface marked (Z). The inner bearing must be installed 218.0 0.3 mm (8.58 .012 in.) below the front surface (Y). Diameter (XX) must be 68.339 0.038 mm (2.6905 .0015 in.) after assembly. 10. Install ring (6) races (4) and bearing (5) on the camshaft. 11. Lubricate cam bearings (9) and the camshaft bearing journals with clean engine oil.12. Install camshaft (3) into the fuel pump housing.

The notch in the lifter must be in line with the dowel in the lifter bore. The lifter must slide up and down freely in