Rating:

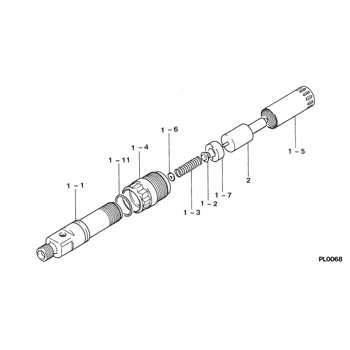

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL 6466A

Engine

6466A

Serial start-end

8601-

Info

Injector Nozzle

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Nozzle Specification:

Parts number

0935003420 JOHN DEERE

Nozzle

0934005341

First opm

25.97-26.95

First op

265-275

Second om

-

Second op

-

Torquen

-

Torque

-

Prelift

-

Max lift

Engine

INDUSTRIAL 6466A

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-03420

HOLDER & NOZZLE SE

Information:

Introduction

This Special Instruction provides the rework procedure for the installation of the 254-4334 Check Valve Kit on the 228-5896 Unit Injector Hydraulic Pump Gp and the 228-5898 Unit Injector Hydraulic Pump Gp . The parts kit includes a temporary service bolt that is used during the removal of the fuel transfer pump in order to prevent the body of the unit injector hydraulic pump from separating. Once the fuel transfer pump has been reinstalled onto the HEUI pump, the service bolt is then removed.

The correct procedures and tooling specifications must always be used. Failure to follow any of the procedures may result in damage, malfunction, or possible engine failure.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products.Dispose of all fluids according to local regulations and mandates.

Table 1

Required Tools

Tool Part Number Description

A 194-3533 T20 Torx bit (1)

B 193-9199 T27 Torx bit (1)

C 194-3536 T40 Torx bit (1)

D 6 mm Hex Key Wrench

Torque Wrench (in lb)

Torque Wrench (ft lb)

1U-6396 O-Ring Assembly Compound

( 1 ) Or Equivalent

Table 2

254-4334 Check Valve Kit

Callout Part Number Description Qty

5 227-5904 O-Ring Seal 1

9 256-0302 Service Bolt 1

10 239-2402 Seal 2

11 179-8128 Seal 1

12 254-4302 Check Valve Assembly 7 Removal of the HEUI Pump

Prior to removing the HEUI pump, wash the engine in order to remove all of the dirt from the area that surrounds the HEUI pump. Remove the HEUI pump. Refer to Disassembly and Assembly, "Unit Injector Hydraulic Pump - Remove" for the correct procedure.Note: Do not allow any debris to enter the HEUI pump or the HEUI pump parts. Allowing debris to enter the HEUI pump will cause pump failure.Note: Do not attempt to perform this rework procedure while the HEUI pump is still on the engine.Removing the Fuel Transfer Pump from the HEUI Pump

Use a vise (3) in order to secure the HEUI pump (1) vertically

This Special Instruction provides the rework procedure for the installation of the 254-4334 Check Valve Kit on the 228-5896 Unit Injector Hydraulic Pump Gp and the 228-5898 Unit Injector Hydraulic Pump Gp . The parts kit includes a temporary service bolt that is used during the removal of the fuel transfer pump in order to prevent the body of the unit injector hydraulic pump from separating. Once the fuel transfer pump has been reinstalled onto the HEUI pump, the service bolt is then removed.

The correct procedures and tooling specifications must always be used. Failure to follow any of the procedures may result in damage, malfunction, or possible engine failure.

Keep all parts clean from contaminants.Contaminants may cause rapid wear and shortened component life.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Caterpillar Tools and Shop Products Guide" for tools and supplies suitable to collect and contain fluids on Caterpillar products.Dispose of all fluids according to local regulations and mandates.

Table 1

Required Tools

Tool Part Number Description

A 194-3533 T20 Torx bit (1)

B 193-9199 T27 Torx bit (1)

C 194-3536 T40 Torx bit (1)

D 6 mm Hex Key Wrench

Torque Wrench (in lb)

Torque Wrench (ft lb)

1U-6396 O-Ring Assembly Compound

( 1 ) Or Equivalent

Table 2

254-4334 Check Valve Kit

Callout Part Number Description Qty

5 227-5904 O-Ring Seal 1

9 256-0302 Service Bolt 1

10 239-2402 Seal 2

11 179-8128 Seal 1

12 254-4302 Check Valve Assembly 7 Removal of the HEUI Pump

Prior to removing the HEUI pump, wash the engine in order to remove all of the dirt from the area that surrounds the HEUI pump. Remove the HEUI pump. Refer to Disassembly and Assembly, "Unit Injector Hydraulic Pump - Remove" for the correct procedure.Note: Do not allow any debris to enter the HEUI pump or the HEUI pump parts. Allowing debris to enter the HEUI pump will cause pump failure.Note: Do not attempt to perform this rework procedure while the HEUI pump is still on the engine.Removing the Fuel Transfer Pump from the HEUI Pump

Use a vise (3) in order to secure the HEUI pump (1) vertically