Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

BUS W04D

Engine

W04D

Serial start-end

8304-

Info

Injector Nozzle

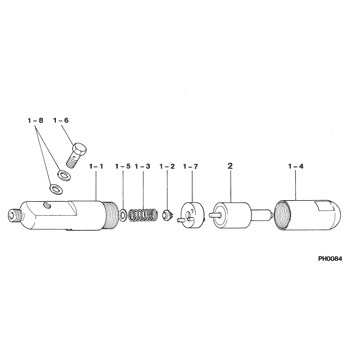

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-02540

HOLDER & NOZZLE SE

000

[01]

09350-02540

HOLDER & NOZZLE SE

Include in ##:

09350-02540

as HOLDER & NOZZLE SE

09350-02540 HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935002540 HINO

Nozzle

0934001470

First opm

21.56

First op

220

Second om

-

Second op

-

Torquen

58.8-78.4

Torque

6.0-8.0

Prelift

-

Max lift

Engine

BUS W04D

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-02540

HOLDER & NOZZLE SE

Information:

Adjustment of the fuel system outside Caterpillar specified limits will not improve fuel efficiency and can result in damage to the engine.

Performance Analysis Report (PAR)

PAR complements a good preventive maintenance program and Caterpillar recommends a regularly scheduled PAR analysis to monitor the condition and maintenance requirements of your engine and to ensure your engine is operating at peak efficiency.Potential problems can be identified early, thus preventing unnecessary repair costs and unscheduled downtime. Consult your Caterpillar dealer for complete information and assistance in establishing a PAR program for your engine.PAR reflects the results of various tests normally conducted by your Caterpillar dealer for the purpose of: * confirming your engine is operating efficiently and within specification.* identifying potential problems.* determining components or systems that should be adjusted, replaced, etc.Approximately 80 to 85% of your truck engine's operation and maintenance cost is the cost of the fuel. Therefore, substantial cost reductions can be achieved by keeping your engine operating at peak efficiency. The fuel economy and performance of the engine is affected by the truck specifications, how it is operated and the condition of the engine. Each plays an important part in minimizing your overall owning and operating cost.Caterpillar has an exclusive Performance Analysis Report (PAR) Program that can help you keep the engine portion of this equation up to PAR. The PAR Program uses a chassis dynamometer to test the engine under load, over its full operating range.Obtain at PM Level 2

Do not attempt to use PAR until the first engine oil change. This allows for sufficient break-in of the engine, drive train and tires. Anytime after is appropriate for a PAR test. Fuel rate and turbocharger boost will be measured under load at five engine speeds and compared to factory specifications. Fuel rate and boost are the primary indicators of your engine's performance and the analysis of this data will help pinpoint potential problems faster.Wheel horsepower (kW) will also be recorded during the initial PAR test to establish your truck's exact wheel horsepower (kW) over its full operating range. This power can then be compared to the power of subsequent PAR tests. Power available at the wheels is not only the result of the condition of the engine, but also the transmission, drive axle(s), brakes, tires and engine drive accessories.A PAR test for engine fuel rate and boost will determine if the engine is operating up to PAR. A comparison of wheel horsepower (kW) to the wheel horsepower (kW) recorded at the initial PAR test will not only be helpful in the analysis of engine condition but is also useful in determining if further investigation of chassis components and engine-driven accessories is necessary.