Rating:

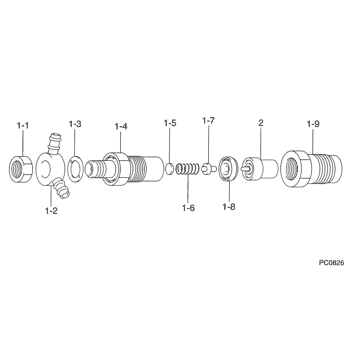

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL Z400

Engine

Z400

Serial start-end

8210-

Info

Injector Nozzle

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-02440

HOLDER & NOZZLE SE

Include in ##:

09350-02440

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935002440 KUBOTA

Nozzle

0934001160

First opm

13.72-14.70

First op

140-150

Second om

-

Second op

-

Torquen

-

Torque

-

Prelift

-

Max lift

Engine

INDUSTRIAL Z400

Information

Cross reference number

Part num

Firm num

Firm

Name

09350-02440

HOLDER & NOZZLE SE

Information:

Engine Crankcase

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the oil system.

Check Oil Level

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to calibrating the oil level gauge in the Dipsticks section of this manual or consult your Caterpillar dealer before operating the engine. 3. Add oil if necessary. See Refill Capacities and Lubricant Specifications for the size of your engine crankcase and proper oil to use. Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary filters, refer to the OEM or manufacturer's instructions.Leaks and Loose Connections

Inspect the Engine

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before servicing. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses

Make sure you read and understand the information in the Lubricant Specifications section of this manual before you proceed with maintenance of the oil system.

Check Oil Level

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. 2. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the ENGINE STOPPED side of the dipstick. Do not fill the crankcase above the FULL RANGE zone. Operating your engine when the oil level is above the FULL RANGE zone could cause your crankshaft to dip into the oil. If this happens, the air bubbles created from the crankshaft dipping into the oil will reduce the lubricating characteristics of your oil and would result in the loss of power.If the dipstick does not have a FULL mark in the FULL RANGE zone, refer to calibrating the oil level gauge in the Dipsticks section of this manual or consult your Caterpillar dealer before operating the engine. 3. Add oil if necessary. See Refill Capacities and Lubricant Specifications for the size of your engine crankcase and proper oil to use. Remote mounted or auxiliary filters require additional oil. For all information pertaining to auxiliary filters, refer to the OEM or manufacturer's instructions.Leaks and Loose Connections

Inspect the Engine

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed.Keep a close watch for leaks. If leaking is observed, find the source and correct the leak. If leaking is suspected, check the fluid levels more frequently than the recommended intervals prescribed in this publication. Continue monitoring fluid levels until a leak is found and fixed, or until the suspicion for a leak has been proven to be unwarranted.* Wipe all fittings, caps and plugs before servicing. * Inspect the radiator for leaks and trash build-up. * Inspect the radiator hoses