Rating:

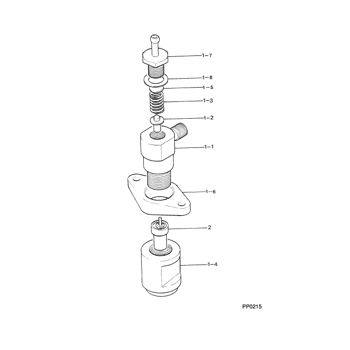

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL KE70

Engine

KE70

Serial start-end

7508-

Info

Injector Nozzle

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-01630

HOLDER & NOZZLE SE

Include in ##:

09350-01630

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935001630 MITSUBISHI

Nozzle

0934000010

First opm

11.76-12.74

First op

120-130

Second om

-

Second op

-

Torquen

58.8-78.4

Torque

6.0-8.0

Prelift

-

Max lift

Engine

INDUSTRIAL KE70

Information

Cross reference number

Part num

Firm num

Firm

Name

09350-01630

HOLDER & NOZZLE SE

Information:

Start By:a. remove crankshaft vibration damper and pulley

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

When replacement of the front seal is made, a replacement of the wear sleeve must also be made.

1. Remove the two bolts, washers, clamp (1), retainer (2) and the O-ring seal.2. Use tool (A) and a press to remove seal (3).3. Install the O-ring seal, retainer (2) and the two bolts, washers, and clamp (1). 4. Install tool (C) in the bore of retainer (2) as shown.5. Install tool (B) between tool (C) and the wear sleeve. Turn tool (B) with a wrench until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.6. Remove tool (C) and the wear sleeve by hand.Install Crankshaft Front Seal And Wear Sleeve

1. Install crankshaft front seal (1) and wear sleeve (2) with tool (A) as follows:a. Put clean engine oil on the seal lip of seal (1) and on the outside diameter of wear sleeve (2). Install seal (1) on wear sleeve (2) as shown.b. Use 6V1541 Quick Cure Primer to clean the outside diameter of crankshaft (3) and the inside diameter of wear sleeve (2).c. Put 9S3265 Retaining Compound on the outside diameter of crankshaft (3) and the inside diameter of wear sleeve (2). Make sure the lip of the seal is toward the engine and the outside diameter bevel of the wear sleeve is toward the outside of the engine.d. Put wear sleeve (2) with seal (1) on the front of the crankshaft as shown in illustration B20159P1. Install tool (A). Tighten the bolt in tool (A) until the inside surface of the installer in tooling (A) makes contact with the end of the crankshaft.End By:a. install crankshaft vibration damper and pulley

Perform Scheduled Oil Sampling on oil wetted compartments after performing service work to check for contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.

Keep all parts clean from contaminants. Contaminants put into the system may cause rapid wear and shortened component life.

When replacement of the front seal is made, a replacement of the wear sleeve must also be made.

1. Remove the two bolts, washers, clamp (1), retainer (2) and the O-ring seal.2. Use tool (A) and a press to remove seal (3).3. Install the O-ring seal, retainer (2) and the two bolts, washers, and clamp (1). 4. Install tool (C) in the bore of retainer (2) as shown.5. Install tool (B) between tool (C) and the wear sleeve. Turn tool (B) with a wrench until the edge of the tool makes a flat place (crease) in the wear sleeve. Do this in two or more places until the wear sleeve is loose.6. Remove tool (C) and the wear sleeve by hand.Install Crankshaft Front Seal And Wear Sleeve

1. Install crankshaft front seal (1) and wear sleeve (2) with tool (A) as follows:a. Put clean engine oil on the seal lip of seal (1) and on the outside diameter of wear sleeve (2). Install seal (1) on wear sleeve (2) as shown.b. Use 6V1541 Quick Cure Primer to clean the outside diameter of crankshaft (3) and the inside diameter of wear sleeve (2).c. Put 9S3265 Retaining Compound on the outside diameter of crankshaft (3) and the inside diameter of wear sleeve (2). Make sure the lip of the seal is toward the engine and the outside diameter bevel of the wear sleeve is toward the outside of the engine.d. Put wear sleeve (2) with seal (1) on the front of the crankshaft as shown in illustration B20159P1. Install tool (A). Tighten the bolt in tool (A) until the inside surface of the installer in tooling (A) makes contact with the end of the crankshaft.End By:a. install crankshaft vibration damper and pulley

Perform Scheduled Oil Sampling on oil wetted compartments after performing service work to check for contaminants left in the system following repair. Contaminants put into the system may cause rapid wear and shortened component life.