Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

INDUSTRIAL S6E

Engine

S6E

Serial start-end

7409-

Info

Injector Nozzle

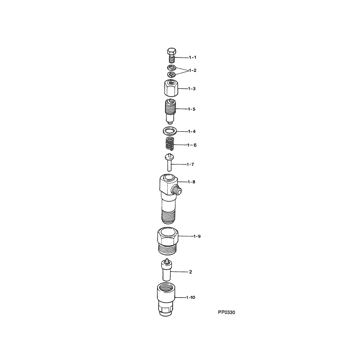

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09350-01410

HOLDER & NOZZLE SE

Include in ##:

09350-01410

as HOLDER & NOZZLE SE

Nozzle Specification:

Parts number

0935001410 MITSUBISHI

Nozzle

0934000620

First opm

11.76-12.74

First op

120-130

Second om

-

Second op

-

Torquen

58.8-78.4

Torque

6.0-8.0

Prelift

-

Max lift

Engine

INDUSTRIAL S6E

Information

Include as Nozzle:

1900000240

as Nozzle

Cross reference number

Part num

Firm num

Firm

Name

09350-01410

HOLDER & NOZZLE SE

Information:

(1) End play for shaft (new) ... 0.114 0.038 mm(.0045 .0015 in) Maximum permissible end play (worn) ... 0.20 mm (.008 in)(2) Thickness of thrust bearing (where thrust rings contact bearing) ... 5.36 0.03 mm (.211 .001 in)(3) Tighten both band clamps with procedure that follows: a. Tighten to ... 14 1.1 N m (125 10 lb in)b. Tap (hit) clamp lightly all around.c. Tighten again to ... 14 1.1 N m (125 10 lb in)

Do not overtighten the clamps.

(4) Diameter of shaft (new) ... 15.997 to 16.005 mm (.6298 to .6301 in) Bore in the bearing (new) ... 16.035 to 16.043 mm (.6313 to .6316 in)Maximum permissible clearance between bearing and shaft (worn) ... 0.05 mm (.002 in)(5) Maximum permissible gap of oil seal ring, measured in bore of housing ... 0.25 mm (.010 in)(6) Install the compressor wheel (at room temperature) as follows: a. See Compressor Wheel Clearance for the correct shim thickness to use.b. Put compressor wheel on the shaft.c. Put a small amount of clean engine oil on the threads.d. Tighten the nut to 14 to 17 N m (125 to 150 lb in).

Do not bend or add stress to the shaft when nut is loosened or tightened.

e. Remove nut from shaft and apply 6V1541 Quick Cure Primer on the threads of the shaft and nut followed by application of 9S3265 Retaining Compound.f. Tighten nut to 4 N m (30 lb in).g. Tighten nut more as follows: For 99.0 mm (3.90 in) diameter compressor wheels, tighten the nut an additional 90°.For 86.4 mm (3.40 in) diameter compressor wheels, tighten the nut an additional 60°.(7) Shims. See Compressor Wheel Clearance for the correct shim thickness to use.(8) Thickness of each thrust ring ... 2.553 0.013 mm (.1005 .0005 in)(9) Bore in housing (new) ... 24.994 to 25.006 mm (.9840 to .9845 in) Outside diameter of the bearing (new) ... 24.882 to 24.892 mm (.9796 to .9800 in)Maximum permissible clearance between bearing and bore in housing (worn) ... 0.15 mm (.006 in)Torque for four nuts (put 5P3931 Anti-Seize Compound on threads) and bolts that hold the turbocharger to the exhaust manifold ... 55 5 N m (40 4 lb ft) Put clean engine oil in the oil inlet of the turbocharger after assembly or before installation to provide start up lubrication and/or storage protection.Compressor Wheel Clearance

a. Remove the compressor wheel from the cartridge group and place the wheel in the compressor housing. Center the wheel in the housing.b. Measure the distance from the compressor housing mounting face to the compressor wheel seating face. Measure four places at approximately 90° increments. This is dimension "A" (Fig. 1).c. Assemble the cartridge group complete except for the compressor wheel and shims. Hold the turbine wheel-shaft assembly toward the compressor end against the thrust bearing. Measure the distance from

Do not overtighten the clamps.

(4) Diameter of shaft (new) ... 15.997 to 16.005 mm (.6298 to .6301 in) Bore in the bearing (new) ... 16.035 to 16.043 mm (.6313 to .6316 in)Maximum permissible clearance between bearing and shaft (worn) ... 0.05 mm (.002 in)(5) Maximum permissible gap of oil seal ring, measured in bore of housing ... 0.25 mm (.010 in)(6) Install the compressor wheel (at room temperature) as follows: a. See Compressor Wheel Clearance for the correct shim thickness to use.b. Put compressor wheel on the shaft.c. Put a small amount of clean engine oil on the threads.d. Tighten the nut to 14 to 17 N m (125 to 150 lb in).

Do not bend or add stress to the shaft when nut is loosened or tightened.

e. Remove nut from shaft and apply 6V1541 Quick Cure Primer on the threads of the shaft and nut followed by application of 9S3265 Retaining Compound.f. Tighten nut to 4 N m (30 lb in).g. Tighten nut more as follows: For 99.0 mm (3.90 in) diameter compressor wheels, tighten the nut an additional 90°.For 86.4 mm (3.40 in) diameter compressor wheels, tighten the nut an additional 60°.(7) Shims. See Compressor Wheel Clearance for the correct shim thickness to use.(8) Thickness of each thrust ring ... 2.553 0.013 mm (.1005 .0005 in)(9) Bore in housing (new) ... 24.994 to 25.006 mm (.9840 to .9845 in) Outside diameter of the bearing (new) ... 24.882 to 24.892 mm (.9796 to .9800 in)Maximum permissible clearance between bearing and bore in housing (worn) ... 0.15 mm (.006 in)Torque for four nuts (put 5P3931 Anti-Seize Compound on threads) and bolts that hold the turbocharger to the exhaust manifold ... 55 5 N m (40 4 lb ft) Put clean engine oil in the oil inlet of the turbocharger after assembly or before installation to provide start up lubrication and/or storage protection.Compressor Wheel Clearance

a. Remove the compressor wheel from the cartridge group and place the wheel in the compressor housing. Center the wheel in the housing.b. Measure the distance from the compressor housing mounting face to the compressor wheel seating face. Measure four places at approximately 90° increments. This is dimension "A" (Fig. 1).c. Assemble the cartridge group complete except for the compressor wheel and shims. Hold the turbine wheel-shaft assembly toward the compressor end against the thrust bearing. Measure the distance from