Rating:

Information holder & nozzle se Denso

Product

Nozzle & Nozzle Holder

Vehicle engine

CANTER 4DQ

Engine

4DQ

Serial start-end

8001-

Info

Injector Nozzle

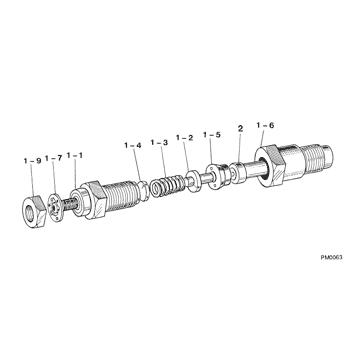

Components :

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

Nozzle Specification:

Parts number

0935000180 MITSUBISHI

Nozzle

0934000090

First opm

11.76-12.74

First op

120-130

Second om

-

Second op

-

Torquen

58.8-78.4

Torque

6.0-8.0

Prelift

-

Max lift

Engine

CANTER 4DQ

Information

Include as Nozzle:

Cross reference number

Part num

Firm num

Firm

Name

09350-00180

HOLDER & NOZZLE SE

Information:

Environmental Considerations

Mount the monitor in a panel or in an enclosure in order to protect the internal circuitry.Provide adequate ventilation in the enclosure. Also, consider heat produced by other devices in the enclosure. The ambient temperature around the monitor must be maintained between 5 °C (41 °F) and 50 °C (122 °F). Make sure that you provide provisions for accessing the back panel and side panels of the monitor. Installing components and removing components requires access to the panels. The floppy disk drive is also accessed through the panels. Refer to Illustration 1.

Illustration 1 g00857541

Mounting ClearancesNote: The dimensions in Illustration 1 are only applicable if the monitor has adequate ventilation. Cooling methods must be used in order to lower air temperature within the enclosure.Mounting Hardware

Table 1

Item Description Quantity Use For

Self-locking nuts #10-32 10 (8 required) Panel or enclosure mounting In addition to the tools that are required in order to make the cut for the panel, you will need the following tools:

Drill

9.525 mm (3/8 inch) socket

15 cm (6 inch) extension rod (minimum)

Socket driver (in/lb. torque wrench recommended)

RulerPanel Mounting

In order to install the monitor in a panel, perform the following procedure:

Cut an opening in the panel by using the dimensions that are provided. Drill eight 6.4 mm (0.25 inch) holes for the mounting studs. Refer to Installation, "Dimensions" for more information.

Make sure that the sealing gasket is properly positioned on the terminal. This gasket forms a compression seal. Do not use sealing compounds.

Place the monitor in the opening in the panel. Align the studs with the mounting holes.

Install the eight self-locking nuts. Hand tighten the self-locking nuts.

Illustration 2 g00857579

Torque Sequence

Alternately tighten the self-locking nuts with the 9.525 mm (3/8 inch) socket. Tighten the nuts until the monitor is held firmly against the panel. The amount of torque that is required increases significantly as the gasket reaches the proper compression. Tighten the nuts to a torque of 2.7 N m (24 lb in). Refer to Illustration 2 for the recommended tightening sequence.Note: Tighten the nuts to a torque of 2.7 N m (24 lb in) in order to provide a proper seal and prevent damage to the monitor.

Mount the monitor in a panel or in an enclosure in order to protect the internal circuitry.Provide adequate ventilation in the enclosure. Also, consider heat produced by other devices in the enclosure. The ambient temperature around the monitor must be maintained between 5 °C (41 °F) and 50 °C (122 °F). Make sure that you provide provisions for accessing the back panel and side panels of the monitor. Installing components and removing components requires access to the panels. The floppy disk drive is also accessed through the panels. Refer to Illustration 1.

Illustration 1 g00857541

Mounting ClearancesNote: The dimensions in Illustration 1 are only applicable if the monitor has adequate ventilation. Cooling methods must be used in order to lower air temperature within the enclosure.Mounting Hardware

Table 1

Item Description Quantity Use For

Self-locking nuts #10-32 10 (8 required) Panel or enclosure mounting In addition to the tools that are required in order to make the cut for the panel, you will need the following tools:

Drill

9.525 mm (3/8 inch) socket

15 cm (6 inch) extension rod (minimum)

Socket driver (in/lb. torque wrench recommended)

RulerPanel Mounting

In order to install the monitor in a panel, perform the following procedure:

Cut an opening in the panel by using the dimensions that are provided. Drill eight 6.4 mm (0.25 inch) holes for the mounting studs. Refer to Installation, "Dimensions" for more information.

Make sure that the sealing gasket is properly positioned on the terminal. This gasket forms a compression seal. Do not use sealing compounds.

Place the monitor in the opening in the panel. Align the studs with the mounting holes.

Install the eight self-locking nuts. Hand tighten the self-locking nuts.

Illustration 2 g00857579

Torque Sequence

Alternately tighten the self-locking nuts with the 9.525 mm (3/8 inch) socket. Tighten the nuts until the monitor is held firmly against the panel. The amount of torque that is required increases significantly as the gasket reaches the proper compression. Tighten the nuts to a torque of 2.7 N m (24 lb in). Refer to Illustration 2 for the recommended tightening sequence.Note: Tighten the nuts to a torque of 2.7 N m (24 lb in) in order to provide a proper seal and prevent damage to the monitor.