Rating:

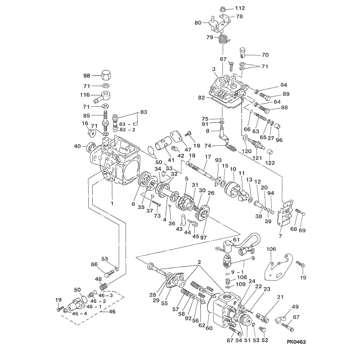

Information head sub-assy, dis Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

096400-1330 Rotor Head 0964001330 Head Rotor for Diesel for VE Pump

Generic 096400-1330 Rotor Head 0964001330 Head Rotor For Diesel For VE Pump

Generic 096400-1330 Rotor Head 0964001330 Head Rotor For Diesel For VE Pump

Hacus - Forklift FPE262791 Head Rotor Assy 15Z Hacus Aftermarket - New

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

Hacus HIGH-QUALITY CONSTRUCTION: Made with premium materials; built to withstand the demands of industrial environments; offering excellent resistance to wear; corrosion; and mechanical stress. || VERSATILE COMPATIBILITY: Engineered to fit a wide range of forklift models; making it a versatile choice for various equipment configurations. || SAFETY FIRST - FPE products are ready for use with all certifications. || LEADING THE INDUSTRY - FPE is a leader in forklift products and accessories. We take pride in making the highest quality, premium, reliable forklifts on the market. || All products tested for durability, reliability, and performance.

You can buy:

Include in ##:

09600-06261

as HEAD SUB-ASSY, DIS

Cross reference number

Part num

Firm num

Firm

Name

09640-01330

22140-1701

HEAD SUB-ASSY, DIS

0964001330

22140-17010

TOYOTA

HEAD SUB-ASSY, DIS

Information:

Oil seals

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.