Rating:

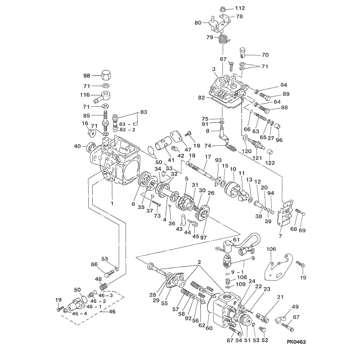

Information head sub-assy, dis Denso

Compare Prices: .

As an associate, we earn commssions on qualifying purchases through the links below

iDEESEEL 096400-1330 Rotor Head 0964001330 Head Rotor Diesel VE Pump (Quantity: 2 Pieces/Lot) iDEESEEL

Generic

Generic

QINGMO-AUTO pump plunger OEM 22140-17010 096400-1330 2214017010 0964001330

QINGMO-AUTO Thank you for visiting our store. Our brand, QINGMO-AUTO, provides you with high-quality service. || Please confirm before purchasing whether the image and number displayed on this link match your old item. If there is any inconsistency, please provide pictures, numbers or your VIN of the old parts for reference, in order to ensure that the product you purchased is fully functional. || This product is a professional automotive accessory. It is recommended to go to a professional repair shop for installation. || If you have any after-sales issues with this product, please contact QINGMO-AUTO, and we will provide you with answers and suggestions after sale. || Your package includes:1 PCS pump plunger OEM 22140-17010 096400-1330 2214017010 0964001330

QINGMO-AUTO Thank you for visiting our store. Our brand, QINGMO-AUTO, provides you with high-quality service. || Please confirm before purchasing whether the image and number displayed on this link match your old item. If there is any inconsistency, please provide pictures, numbers or your VIN of the old parts for reference, in order to ensure that the product you purchased is fully functional. || This product is a professional automotive accessory. It is recommended to go to a professional repair shop for installation. || If you have any after-sales issues with this product, please contact QINGMO-AUTO, and we will provide you with answers and suggestions after sale. || Your package includes:1 PCS pump plunger OEM 22140-17010 096400-1330 2214017010 0964001330

Parts# 22140-17010 096400-1330 2214017010 0964001330 Pump Plunger 1pc/Set DRAGOON-BRO

DRAGOON-BRO PARTS# 22140-17010 096400-1330 2214017010 0964001330 || Check your parts number before purchasing or send VIN to us,we will check the right parts number for you. || High performance and superior quality. || If you have any questions,please be free to contact us. || DRAGOON-BRO

DRAGOON-BRO PARTS# 22140-17010 096400-1330 2214017010 0964001330 || Check your parts number before purchasing or send VIN to us,we will check the right parts number for you. || High performance and superior quality. || If you have any questions,please be free to contact us. || DRAGOON-BRO

You can buy:

Include in ##:

09600-06261

as HEAD SUB-ASSY, DIS

Cross reference number

Part num

Firm num

Firm

Name

09640-01330

22140-1701

HEAD SUB-ASSY, DIS

0964001330

22140-17010

TOYOTA

HEAD SUB-ASSY, DIS

Information:

Oil seals

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.

When installing oil seals, observe the following.Installation of Oil Seals to Housings

(a) Check the seal lip for scratches and damage, and be sure to position the lip correctly.(b) Apply a small amount of grease to the periphery (housing contact surface) of the oil seal before installation.(c) Use an oil seal driver that guides the seal lip and presses the seal periphery, as shown in the diagram on the right. Striking the oil seal directly with a hammer causes seal damage and results in oil leaks.

Oil seal driverInstallation of Oil Seals to Shafts

(a) Apply grease to the oil seal lip.(b) Use an oil seal guide similar to the one shown in the diagram when installing an oil seal over the stepped portion, splines, threads or key grooves.

Oil seal guideO-rings

Use an O-ring guide similar to the one shown in the diagram when installing an O-ring over the stepped portion, splines, threads or key grooves. Be sure to apply a small amount of grease to the O-ring before installation.

O-ring guideBearings

(1) When installing a bearing, be sure to push the inner or outer race that fits into the installation position. (When the inner race fits into the installation position, push the inner race into position. When the outer race fits into the installation position, push the outer race into position.) Be sure to use a bearing driver similar to the one shown in the diagram.

Bearing driver(2) Use of a press minimizes the impact on the bearing and ensures proper installation.

Using press for bearing installationLock Plates

Be sure to bend lock plates. The diagram on the right shows the methods of bending representative lock plates.

Bending lock plateSplit Pins and Spring Pins

Generally, new split pins should be installed whenever split pins are removed. Be sure to bend split pins. Be sure to check spring pins for secure installation.