Rating:

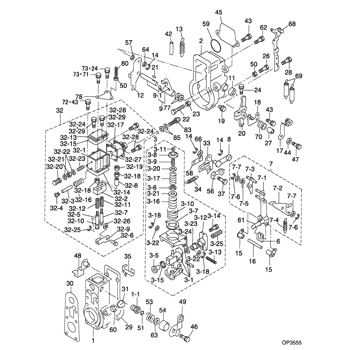

Information governor assy, mec Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09130-06481

GOVERNOR ASSY, MEC

R801H

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09130-06481

GOVERNOR ASSY, MEC

Information:

Engine Valve Lash

Check/Adjust

Initial valve lash adjustment on new, or rebuilt engines is recommended and should have been performed at the first normally scheduled oil change interval (250 Hours) due to initial wear and seating of valve train components. Subsequent adjustments should be made at every 3000 Hours.Set the valve lash clearance to the nominal value given in the Valve Lash Setting chart shown previously in this manual. Refer to the information in the Every 250 Hour maintenance and the Service Manual for the procedure.Cooling System

Clean/Flush Coolant

Do not perform this maintenance until you read and understand the material in the Safety and Cooling System Specifications sections of this publication.Caterpillar does not recommend the use of cooling system solutions that are intended to stop leaks. Use of these products may result in excessive internal deposits that could reduce the engine's heat transfer characteristics as well as damage to the water pump seals.This procedure is to be used for normal maintenance of cooling systems surfaces to return to "like new" condition. For heavy build-up of scale and deposits, a severe acid-type, commercial cleaner or mechanical cleaning will be required.

Performing maintenance on the cooling system is important because the cooling system has a direct effect on the operation and service life of the engine.Improper maintenance can result in a variety of problems that could shorten the engine's service life, reduce the efficiency of the cooling system, result in poor engine performance, and in some cases, result in an increase in fuel consumption.Add Cooling System Cleaner

There are two types of cooling system cleaners available. One is the 6V4511 Standard-Type in the 1.9 L (1/2 U.S. gal) container and the other is the 4C4611 Fast Acting-Type in the 3.8 L (1 U.S. gal) container.The Standard-Type requires approximately 120 hours of engine operation to remove scale, lime and other debris. The Fast Acting-Type requires only 90 minutes of engine operation. Both types must remain in the system for a minimum of specified time to work properly, however, neither type will harm the engine if left in for a longer period of time.The Standard-Type must be added before the Every 3000 Hour maintenance interval. Add 1 liter (1 U.S. quart) of Caterpillar Cooling System Cleaner, Standard-Type, for every 15 liter (4 U.S. gallon) of cooling system capacity. Continue to operate the engine for the specified time before draining.The Fast Acting-Type may be added just prior to draining (such as the same day of a day trip) and the system cleaned and flushed after operating for the specified time period. Follow the directions on the container.Drain

When you drain, clean, flush and replace the coolant, small particles, undesirable chemicals, scale and other deposit formations are removed. These deposits reduce the necessary heat transfer characteristics of the cooling system.Coolant water drain groups, installed in the jacket water pumps, may be available for draining engine coolant. Contact your Caterpillar dealer for assistance.

Check the coolant level only after the engine has been stopped and the fill cap is cool enough to

Check/Adjust

Initial valve lash adjustment on new, or rebuilt engines is recommended and should have been performed at the first normally scheduled oil change interval (250 Hours) due to initial wear and seating of valve train components. Subsequent adjustments should be made at every 3000 Hours.Set the valve lash clearance to the nominal value given in the Valve Lash Setting chart shown previously in this manual. Refer to the information in the Every 250 Hour maintenance and the Service Manual for the procedure.Cooling System

Clean/Flush Coolant

Do not perform this maintenance until you read and understand the material in the Safety and Cooling System Specifications sections of this publication.Caterpillar does not recommend the use of cooling system solutions that are intended to stop leaks. Use of these products may result in excessive internal deposits that could reduce the engine's heat transfer characteristics as well as damage to the water pump seals.This procedure is to be used for normal maintenance of cooling systems surfaces to return to "like new" condition. For heavy build-up of scale and deposits, a severe acid-type, commercial cleaner or mechanical cleaning will be required.

Performing maintenance on the cooling system is important because the cooling system has a direct effect on the operation and service life of the engine.Improper maintenance can result in a variety of problems that could shorten the engine's service life, reduce the efficiency of the cooling system, result in poor engine performance, and in some cases, result in an increase in fuel consumption.Add Cooling System Cleaner

There are two types of cooling system cleaners available. One is the 6V4511 Standard-Type in the 1.9 L (1/2 U.S. gal) container and the other is the 4C4611 Fast Acting-Type in the 3.8 L (1 U.S. gal) container.The Standard-Type requires approximately 120 hours of engine operation to remove scale, lime and other debris. The Fast Acting-Type requires only 90 minutes of engine operation. Both types must remain in the system for a minimum of specified time to work properly, however, neither type will harm the engine if left in for a longer period of time.The Standard-Type must be added before the Every 3000 Hour maintenance interval. Add 1 liter (1 U.S. quart) of Caterpillar Cooling System Cleaner, Standard-Type, for every 15 liter (4 U.S. gallon) of cooling system capacity. Continue to operate the engine for the specified time before draining.The Fast Acting-Type may be added just prior to draining (such as the same day of a day trip) and the system cleaned and flushed after operating for the specified time period. Follow the directions on the container.Drain

When you drain, clean, flush and replace the coolant, small particles, undesirable chemicals, scale and other deposit formations are removed. These deposits reduce the necessary heat transfer characteristics of the cooling system.Coolant water drain groups, installed in the jacket water pumps, may be available for draining engine coolant. Contact your Caterpillar dealer for assistance.

Check the coolant level only after the engine has been stopped and the fill cap is cool enough to