Rating:

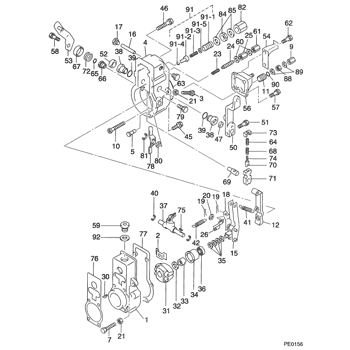

Information governor assy, mec Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09080-07101

GOVERNOR ASSY, MEC

RSV

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09080-07101

GOVERNOR ASSY, MEC

Information:

2-12.2 Turn the crankshaft in the direction of engine rotation until the valves opposite the cylinder to be adjusted overlap.Fig. 2-1 and table below

2-2 Note for Refitment:The exhaust valve is left-hand as viewed from the exhaust air side.Fig. 2-2

2-33. Release locknut of adjusting screw and adjust rocker arm/valve stem clearance.Retighten locknut.Fig. 2-34. Recheck clearance and readjust if necessary.

2-45. Apply sealing compound to new gaskets for rocker chamber cover(s) and fit cover(s).Fig. 2-4 Checking The Compression Pressure

The specified pressure applies to min. 150/min starting speed of engine and 20°C reference temperature at sea-level. Prior to checking, run up engine briefly to medium speed, so the combustion chamber will be sufficiently sealed by an oil film. Perform check at zero delivery of injection pump.

2-51. Remove injector and in its place insert and secure adapter with seal.Fig. 2-5, left Attention:In the case of FL 912 W, remove heater plug and in its place insert adapter for compression pressure recorder.Fig. 2-5, right

2-62. Connect compression pressure gauge.Fig. 2-6

2-73. Take the compression pressure reading.Fig. 2-7

2-8 Important:Check that the individual compression pressures are within the range specified and about equal for all cylinders. Any deviations in pressure between cylinders should not exceed 15%.Fig. 2-8Determining TDC With Setting Device

1. Remove No. 1 rocker chamber cover.2. Turn crankshaft until valves overlap, then give crankshaft another half turn.

2-93. Mount setting device. Using pressure screw of device, press down one rocker arm through 5-6 mm.Fig. 2-9

2-104. Fit dial gauge with preload.Fig. 2-10

2-115. Secure graduated scale to V-belt pulley and fix pointer to dowel sleeve.Fig. 2-11 If engine is installed in vehicle, use graduated dial segment No. 100940.6. Set pointer to "O" on scale.7. Turn crankshaft carefully in nominal direction until piston pushes up the valve. Slowly turn farther until gauge pointer changes the direction. Set gauge at "O"8. Turn back crankshaft through about one revolution of gauge pointer, then again in original direction up to 0, 1 mm (10 graduations) from O-position. Read crankshaft position from scale and record.9. Turn crankshaft in running direction beyond "O" through about one revolution of the