Rating:

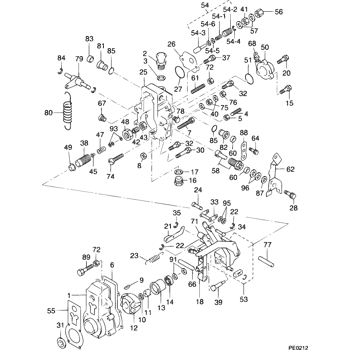

Information governor assy, mec Denso

KIT List:

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09080-03620

GOVERNOR ASSY, MEC

RSV

22410-77123

TOYOTA

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09080-03620

22410-7712

GOVERNOR ASSY, MEC

0908003620

22410-77123

TOYOTA

GOVERNOR ASSY, MEC

Information:

If the engine has been operating at high load, run at low idle for at least three minutes before stopping. This cool down will reduce and stabilize internal engine coolant and oil temperatures before stopping the engine.If the engine has been operating at low loads, run the engine at low idle for 30 seconds before stopping.Make sure the shutoff procedure is understood. Refer to the Stopping the Engine instructions in the Generator Set Control Panel topic in this publication. Use the following general guidelines for stopping the engine.1. Open the Main electrical circuit breaker/Remove load from engine.2. Move the governor control to no more than half engine speed. Run the engine for three to five minutes.3. Reduce the engine speed to low idle.4. The engine may be stopped by using the Woodward Governor (if equipped), the Mechanical Governor (if equipped), or the solenoid shutoff switch.Woodward Actuator (If Equipped)

If equipped with a Woodward Actuator, move the control lever upward or forward, depending on the installation. Hold the lever to the OFF or STOP position until the engine stops.Mechanical Governor Control

A manual shutoff lever is provided to shut off the fuel from the fuel injection pump and override the governor control. The manual shutoff lever is located on the side of the pump.The engine can be shut OFF by rotating and holding the manual shutoff lever in the clockwise (CW) direction. If equipped with a Mechanical Governor Control, to move control to the SHUT OFF position: pull upward on the vernier hand grip while pushing down on thumb button. This shutdown will only move the fuel control linkage (rack) to the FUEL-OFF position. This does not shut off the air inlet.Solenoid Shutoff

Move the Control Panel Engine Control Switch (ECS, if equipped) to the STOP position.After Stopping the Engine

1. Fill the fuel tank to prevent accumulation of moisture in the fuel.2. Check the coolant level. Maintain the cooling system to 13 mm (1/2 inch) from bottom of the fill pipe. If freezing temperatures are expected, allow the radiator and engine jacket water system to cool, then check the coolant for proper antifreeze protection. The cooling system must be protected against freezing to the lowest expected ambient (outside) temperature. Add the proper coolant and water mixture if necessary.3. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the dipstick.4. Repair any leaks, perform minor adjustments, tighten loose bolts, etc. 5. Note the service hour meter reading. Perform periodic maintenance as instructed in the Maintenance Schedule.

If equipped with a Woodward Actuator, move the control lever upward or forward, depending on the installation. Hold the lever to the OFF or STOP position until the engine stops.Mechanical Governor Control

A manual shutoff lever is provided to shut off the fuel from the fuel injection pump and override the governor control. The manual shutoff lever is located on the side of the pump.The engine can be shut OFF by rotating and holding the manual shutoff lever in the clockwise (CW) direction. If equipped with a Mechanical Governor Control, to move control to the SHUT OFF position: pull upward on the vernier hand grip while pushing down on thumb button. This shutdown will only move the fuel control linkage (rack) to the FUEL-OFF position. This does not shut off the air inlet.Solenoid Shutoff

Move the Control Panel Engine Control Switch (ECS, if equipped) to the STOP position.After Stopping the Engine

1. Fill the fuel tank to prevent accumulation of moisture in the fuel.2. Check the coolant level. Maintain the cooling system to 13 mm (1/2 inch) from bottom of the fill pipe. If freezing temperatures are expected, allow the radiator and engine jacket water system to cool, then check the coolant for proper antifreeze protection. The cooling system must be protected against freezing to the lowest expected ambient (outside) temperature. Add the proper coolant and water mixture if necessary.3. Check the crankcase oil level. Maintain the oil level between the ADD and FULL marks in the FULL RANGE zone on the dipstick.4. Repair any leaks, perform minor adjustments, tighten loose bolts, etc. 5. Note the service hour meter reading. Perform periodic maintenance as instructed in the Maintenance Schedule.