Rating:

Information cover sub-assy, go Denso

Include in ##:

09600-02020

as COVER SUB-ASSY, GO

Cross reference number

Part num

Firm num

Firm

Name

09644-00860

22703-5426

COVER SUB-ASSY, GO

0964400860

22703-54262

TOYOTA

COVER SUB-ASSY, GO

Information:

Column Headings

Column headings and arrangement of material can vary from chart to chart according to data requirements for the engines. A brief description of each column heading, note and symbol follows. See Fig. 1.Model

The MODEL column lists the description of the engine, and the serial number range to which the data applies. Be sure to use the data from the correct serial number range for the engine being repaired.Engine Full Load RPM

The column lists the engine speed (under load) at which the rack is positioned to permit maximum allowable amount of fuel to the engine per unit of time. Turbocharger speed, inlet manifold pressure and horsepower output are at their maximum for the listed rack setting. A tolerance of 10 RPM is allowed.Engine High Idle RPM

This column lists the high idle speed of the bare engine when driving a dynamometer. Use the figures in the chart when adjusting high idle in the truck. A tolerance of 30 RPM is allowed in most applications.Brake Horsepower

This column lists the power available at the flywheel, without fan, and within the limitations indicated in the charts. A tolerance of 3% of this value is normal from a new or reconditioned engine.

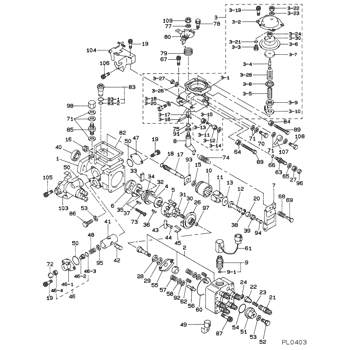

Fig. 1Rack Setting

The rack setting is the distance the rack must travel from the centered (sometimes referred to as zero) position, to supply sufficient fuel, to produce the expected power output of the engine. Rack setting is controlled by a stop bar or torque spring that is located within the governor. The stop bar and/or torque spring limits the maximum travel of the fuel rack. Rack setting procedure is explained and illustrated in the TESTING AND ADJUSTING Section of the applicable service manual.All rack settings are plus (+) settings unless otherwise indicated with a minus (-) sign. See Fig. 2.Torque Spring And Spacer

This column lists the part number and thickness of the torque spring, and only those spacers or shims installed between the torque spring and stop. Any shims located behind the stop are not listed. The dimensions are in inches and are for means of identification.

Fig. 2SINGLE AND DOUBLE ASTERISKS (* and **): These two markings are used only in the column under the heading TORQUE SPRING AND SPACER. The single asterisk (*) denotes the part number of the TORQUE SPRING. The double asterisk (**) denotes the part number of the SPACER.ARROWS: When two or more part numbers apply to more than two successive rack settings, the duplication is shown by an arrow. The arrow will extend from the first rack setting for which the part numbers apply to the rack setting where the part numbers change.DITTO MARKS: Data that applies unchanged for several settings, but consists of only one item, is indicated by ditto marks. See Fig. 2.Turbocharger Assembly

This column lists the part number of the turbocharger used.Occasionally changes are made to a turbocharger that requires assigning a new turbocharger part number.If the change does not affect engine performance, the column will state the either turbocharger can

Column headings and arrangement of material can vary from chart to chart according to data requirements for the engines. A brief description of each column heading, note and symbol follows. See Fig. 1.Model

The MODEL column lists the description of the engine, and the serial number range to which the data applies. Be sure to use the data from the correct serial number range for the engine being repaired.Engine Full Load RPM

The column lists the engine speed (under load) at which the rack is positioned to permit maximum allowable amount of fuel to the engine per unit of time. Turbocharger speed, inlet manifold pressure and horsepower output are at their maximum for the listed rack setting. A tolerance of 10 RPM is allowed.Engine High Idle RPM

This column lists the high idle speed of the bare engine when driving a dynamometer. Use the figures in the chart when adjusting high idle in the truck. A tolerance of 30 RPM is allowed in most applications.Brake Horsepower

This column lists the power available at the flywheel, without fan, and within the limitations indicated in the charts. A tolerance of 3% of this value is normal from a new or reconditioned engine.

Fig. 1Rack Setting

The rack setting is the distance the rack must travel from the centered (sometimes referred to as zero) position, to supply sufficient fuel, to produce the expected power output of the engine. Rack setting is controlled by a stop bar or torque spring that is located within the governor. The stop bar and/or torque spring limits the maximum travel of the fuel rack. Rack setting procedure is explained and illustrated in the TESTING AND ADJUSTING Section of the applicable service manual.All rack settings are plus (+) settings unless otherwise indicated with a minus (-) sign. See Fig. 2.Torque Spring And Spacer

This column lists the part number and thickness of the torque spring, and only those spacers or shims installed between the torque spring and stop. Any shims located behind the stop are not listed. The dimensions are in inches and are for means of identification.

Fig. 2SINGLE AND DOUBLE ASTERISKS (* and **): These two markings are used only in the column under the heading TORQUE SPRING AND SPACER. The single asterisk (*) denotes the part number of the TORQUE SPRING. The double asterisk (**) denotes the part number of the SPACER.ARROWS: When two or more part numbers apply to more than two successive rack settings, the duplication is shown by an arrow. The arrow will extend from the first rack setting for which the part numbers apply to the rack setting where the part numbers change.DITTO MARKS: Data that applies unchanged for several settings, but consists of only one item, is indicated by ditto marks. See Fig. 2.Turbocharger Assembly

This column lists the part number of the turbocharger used.Occasionally changes are made to a turbocharger that requires assigning a new turbocharger part number.If the change does not affect engine performance, the column will state the either turbocharger can