Rating:

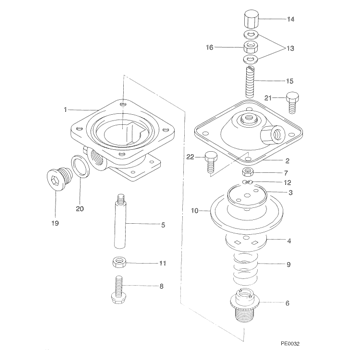

Information compensator sub-as Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

19260-01760

COMPENSATOR SUB-AS

S2243-02080

HINO

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

19260-01760

S2243-0208

COMPENSATOR SUB-AS

1926001760

S2243-02080

HINO

COMPENSATOR SUB-AS

1926001760

S2243-02080-A

HINO

COMPENSATOR SUB-AS

Information:

Engine Compartment

Walk-Around Inspection

Inspect Engine for Leaks and Loose Connections

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan and accessory drive belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed. Check the fluid levels more frequently than the recommended maintenance intervals and continue to monitor fluid levels until any leak is found and fixed.* Wipe all fittings, caps and plugs before performing maintenance to reduce the chance of system contamination.* Inspect all lines, tubes and hoses carefully. Do not use your bare hands to check for leaks. Tighten all connections to the recommended torque.Inspect:* Radiator and ATAAC core for leaks and trash build-up.* Radiator and ATAAC air intake system hoses and elbows for cracks and loose clamps (especially in arctic conditions).* Fan and accessory drive belts for cracks, breaks or other damage (especially in arctic conditions). Inspect:* Water pump for coolant leaks. The water pump seal is lubricated by coolant and it is normal for a small amount of leakage to occur as the engine cools down and parts contract. If leaks are found, check the coolant level frequently and continue to monitor the level until the water pump is repaired. Excessive coolant leakage may indicate the need to replace the water pump seal. For removal and installation of water pumps and/or seals, see the Service Manual for this engine or consult Caterpillar.Inspect:* Lube system for leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers.* Fuel system for leaks, loose fuel line fittings and loose or worn hoses.* Engine wiring and harnesses for loose connections and worn or frayed wires (especially in arctic conditions).* Engine electrical grounding system for good connections and condition. Some vehicles will use a starter to battery ground strap. If a starting motor change is made, consult Caterpillar to make sure that the proper grounding procedures are followed for that model starting motor.* All guards must be in place. Repair or replace missing or damaged guards.Engine Crankcase

Make sure you read and understand the information in the Safety and Lubricant Specifications sections of this Manual before you proceed with maintenance of the crankcase lube oil system.

Check Oil Level

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. DO NOT check the oil level with the engine running. Refer to the Refill Capacities chart for the proper amount of oil at oil change time to determine the correct position on the dipstick for your application. If more oil than the specified Refill Capacity is required to reach the OPERATING RANGE (FULL) mark, consult Caterpillar. DO NOT OVERFILL above the OPERATING RANGE (FULL) mark on the dipstick. 2. Maintain the crankcase oil level between the ADD and OPERATING RANGE (FULL) marks on the dipstick. Operating your engine when the

Walk-Around Inspection

Inspect Engine for Leaks and Loose Connections

For maximum service life of your truck engine, make a thorough under the hood inspection before starting the engine. Look for such items as oil or coolant leaks, loose bolts, worn fan and accessory drive belts, loose connections and trash build-up. Remove trash build-up and have repairs made as needed. Check the fluid levels more frequently than the recommended maintenance intervals and continue to monitor fluid levels until any leak is found and fixed.* Wipe all fittings, caps and plugs before performing maintenance to reduce the chance of system contamination.* Inspect all lines, tubes and hoses carefully. Do not use your bare hands to check for leaks. Tighten all connections to the recommended torque.Inspect:* Radiator and ATAAC core for leaks and trash build-up.* Radiator and ATAAC air intake system hoses and elbows for cracks and loose clamps (especially in arctic conditions).* Fan and accessory drive belts for cracks, breaks or other damage (especially in arctic conditions). Inspect:* Water pump for coolant leaks. The water pump seal is lubricated by coolant and it is normal for a small amount of leakage to occur as the engine cools down and parts contract. If leaks are found, check the coolant level frequently and continue to monitor the level until the water pump is repaired. Excessive coolant leakage may indicate the need to replace the water pump seal. For removal and installation of water pumps and/or seals, see the Service Manual for this engine or consult Caterpillar.Inspect:* Lube system for leaks, such as front and rear crankshaft seals, oil pan, oil filters and valve covers.* Fuel system for leaks, loose fuel line fittings and loose or worn hoses.* Engine wiring and harnesses for loose connections and worn or frayed wires (especially in arctic conditions).* Engine electrical grounding system for good connections and condition. Some vehicles will use a starter to battery ground strap. If a starting motor change is made, consult Caterpillar to make sure that the proper grounding procedures are followed for that model starting motor.* All guards must be in place. Repair or replace missing or damaged guards.Engine Crankcase

Make sure you read and understand the information in the Safety and Lubricant Specifications sections of this Manual before you proceed with maintenance of the crankcase lube oil system.

Check Oil Level

The vehicle must be parked on a level surface to perform this maintenance procedure.

1. Check the oil level with the engine stopped. DO NOT check the oil level with the engine running. Refer to the Refill Capacities chart for the proper amount of oil at oil change time to determine the correct position on the dipstick for your application. If more oil than the specified Refill Capacity is required to reach the OPERATING RANGE (FULL) mark, consult Caterpillar. DO NOT OVERFILL above the OPERATING RANGE (FULL) mark on the dipstick. 2. Maintain the crankcase oil level between the ADD and OPERATING RANGE (FULL) marks on the dipstick. Operating your engine when the