Rating:

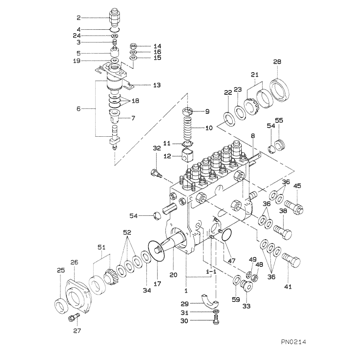

Information body assy, injecti Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

19010-00132

BODY ASSY, INJECTI

NB6

Include in ##:

19010-00132

as BODY ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

19010-00132

BODY ASSY, INJECTI

Information:

Cold Mode Operation (Electronic)

A truck equipped with an Electronic Engine, which after it has completed the cold mode and the cold mode is disabled, cannot be enabled again until the ECM is powered OFF.

The cold start strategy will be activated when the coolant temperature is below 40°F (4.5°C). Once activated, it will continue until the coolant temperature reaches 68°F (20°C). This strategy involves the following steps.1. During cranking the rack limit is .413 inch (10.5 mm) and timing is held at a constant 2° advance.2. After the engine starts, the engine speed is ramped down from 1000 rpm to low idle speed. The ramp down occurs within 70 seconds.3. Timing advance is a speed dependent value with more advance at higher engine speeds.4. If the cold start strategy is active and the ECM measures a vehicle speed, warm mode will be activated.5. A fail-safe timer will disable the cold start strategy after 15 minutes have expired if the warm mode is not yet active. The time needed for the engine to reach the normal mode of operation is usually less than the time necessary for a walk-around-inspection of the vehicle.After Cold Mode strategy is completed, the truck should be operated at low rpm and low power until normal operating coolant temperature 175° to 205°F (79° to 98°C) is reached.The engine will reach operating temperature faster when driven at low rpm and low power demand than when idled at no load. Typically the engine should reach operating temperature when driving through the yard toward the open road.Engine Operation

* Begin operating the engine at low load. After normal oil pressure is reached and the temperature gauge begins to move, the engine may be operated at full load.* To get the vehicle in motion, use a gear that will result in a smooth, easy start to move the load without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly. Interrupted slipping and abrupt clutch engagement put stress on the drive train and waste fuel. It is not necessary to advance the throttle to get the Electronic equipped truck moving from a stop in most instances.* Use progressive shifting to reduce fuel consumption. Progressive shifting is using only the rpm required to make an upshift into the next gear. The amount of rpm required to make an upshift increases as the truck speed increases unless upshifts are made on upgrades. Experience with your truck will show you how much rpm is required to make upshifts under various conditions. Your Electronic engine may be programmed for Low and High Gears RPM Limiting (progressive shift control).* If the truck can be operated in a higher gear after the desired speed is reached, select the highest gear available that will pull the load. By following this recommendation, you will lower your fuel costs. Your engine will be operating at the lowest rpm required to pull the load. Your Electronic engine may be programmed so that Vehicle Speed Limit (VSL)

A truck equipped with an Electronic Engine, which after it has completed the cold mode and the cold mode is disabled, cannot be enabled again until the ECM is powered OFF.

The cold start strategy will be activated when the coolant temperature is below 40°F (4.5°C). Once activated, it will continue until the coolant temperature reaches 68°F (20°C). This strategy involves the following steps.1. During cranking the rack limit is .413 inch (10.5 mm) and timing is held at a constant 2° advance.2. After the engine starts, the engine speed is ramped down from 1000 rpm to low idle speed. The ramp down occurs within 70 seconds.3. Timing advance is a speed dependent value with more advance at higher engine speeds.4. If the cold start strategy is active and the ECM measures a vehicle speed, warm mode will be activated.5. A fail-safe timer will disable the cold start strategy after 15 minutes have expired if the warm mode is not yet active. The time needed for the engine to reach the normal mode of operation is usually less than the time necessary for a walk-around-inspection of the vehicle.After Cold Mode strategy is completed, the truck should be operated at low rpm and low power until normal operating coolant temperature 175° to 205°F (79° to 98°C) is reached.The engine will reach operating temperature faster when driven at low rpm and low power demand than when idled at no load. Typically the engine should reach operating temperature when driving through the yard toward the open road.Engine Operation

* Begin operating the engine at low load. After normal oil pressure is reached and the temperature gauge begins to move, the engine may be operated at full load.* To get the vehicle in motion, use a gear that will result in a smooth, easy start to move the load without increasing engine speed above low idle or slipping the clutch. Engage the clutch smoothly. Interrupted slipping and abrupt clutch engagement put stress on the drive train and waste fuel. It is not necessary to advance the throttle to get the Electronic equipped truck moving from a stop in most instances.* Use progressive shifting to reduce fuel consumption. Progressive shifting is using only the rpm required to make an upshift into the next gear. The amount of rpm required to make an upshift increases as the truck speed increases unless upshifts are made on upgrades. Experience with your truck will show you how much rpm is required to make upshifts under various conditions. Your Electronic engine may be programmed for Low and High Gears RPM Limiting (progressive shift control).* If the truck can be operated in a higher gear after the desired speed is reached, select the highest gear available that will pull the load. By following this recommendation, you will lower your fuel costs. Your engine will be operating at the lowest rpm required to pull the load. Your Electronic engine may be programmed so that Vehicle Speed Limit (VSL)