Rating:

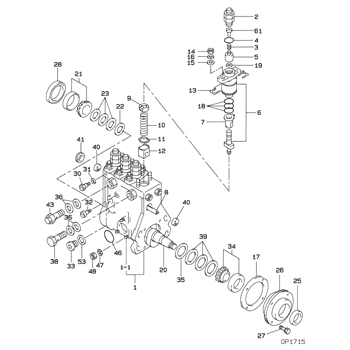

Information body assy, injecti Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09010-09372

BODY ASSY, INJECTI

NB4

Include in ##:

09010-09372

as BODY ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09010-09372

BODY ASSY, INJECTI

Information:

Engine

Steam Clean

Accumulated grease and oil on an engine is a fire hazard. Remove this debris each time a significant quantity of oil is spilled on the engine.

Steam cleaning your engine is a good preventive maintenance practice because it provides you with a way to detect oil and coolant leaks. Repairing an oil or coolant leak upon detection may save you money by avoiding major repairs that could result from low oil or coolant levels.Steam cleaning the engine as recommended will also improve the engine's heat transfer characteristics.Thermostat

Replace Thermostat, Gaskets and Seal

Replacing your thermostat prior to failure is a recommended preventive maintenance practice because it reduces the chances for unscheduled downtime. Failure to replace the thermostat on a regularly scheduled basis could cause severe engine damage and added cost because of damage to other engine components.Since Caterpillar engines incorporate a shunt design cooling system, it is mandatory to always operate the engine with a thermostat.If the thermostat fails in the closed position, it will cause excessive overheating. Excessive overheating could result in cylinder head cracking or piston seizure problems.If the thermostat fails in the open position, it will cause the engine operating temperature to be too low during partial load operation. Low engine operating temperatures during partial loads could cause an excessive carbon build-up inside the cylinder. This excessive carbon build-up could result in accelerated ring and liner wear.Depending on load, a thermostat that fails in a partially opened position will cause either an overheating or an overcooling condition.Caterpillar recommends the replacement of the thermostat on a regularly scheduled basis to be the most cost effective way to operate your engine. All tools shown or mentioned in the following Disassembly and Assembly procedure are available at any Caterpillar dealer.Remove Thermostat

1. Stop the engine and allow to cool. Loosen the coolant filler cap slowly to relieve any pressure and remove the cap.2. Drain the coolant from the cooling system to a level below the thermostat housing. 3. Loosen the hose clamps and remove the radiator hose from the thermostat housing. 4. Remove the thermostat and gasket from the thermostat housing.Install Thermostat

5. Install a new thermostat in the thermostat housing.

If the thermostat is installed wrong, it will cause the engine to overheat.

6. Install a new gasket and the water outlet pipe on the thermostat housing.7. Install the radiator hose and tighten the hose clamps.8. Add coolant to the cooling system to bring it to the proper level by mixing a solution of acceptable water, Caterpillar Antifreeze or equivalent and Supplemental Coolant Additive (Conditioner) if NOT using Caterpillar Antifreeze, or if equipped with a coolant conditioner element, install the appropriate element.Refer to the Cooling System - Clean/Flush Coolant topic

Steam Clean

Accumulated grease and oil on an engine is a fire hazard. Remove this debris each time a significant quantity of oil is spilled on the engine.

Steam cleaning your engine is a good preventive maintenance practice because it provides you with a way to detect oil and coolant leaks. Repairing an oil or coolant leak upon detection may save you money by avoiding major repairs that could result from low oil or coolant levels.Steam cleaning the engine as recommended will also improve the engine's heat transfer characteristics.Thermostat

Replace Thermostat, Gaskets and Seal

Replacing your thermostat prior to failure is a recommended preventive maintenance practice because it reduces the chances for unscheduled downtime. Failure to replace the thermostat on a regularly scheduled basis could cause severe engine damage and added cost because of damage to other engine components.Since Caterpillar engines incorporate a shunt design cooling system, it is mandatory to always operate the engine with a thermostat.If the thermostat fails in the closed position, it will cause excessive overheating. Excessive overheating could result in cylinder head cracking or piston seizure problems.If the thermostat fails in the open position, it will cause the engine operating temperature to be too low during partial load operation. Low engine operating temperatures during partial loads could cause an excessive carbon build-up inside the cylinder. This excessive carbon build-up could result in accelerated ring and liner wear.Depending on load, a thermostat that fails in a partially opened position will cause either an overheating or an overcooling condition.Caterpillar recommends the replacement of the thermostat on a regularly scheduled basis to be the most cost effective way to operate your engine. All tools shown or mentioned in the following Disassembly and Assembly procedure are available at any Caterpillar dealer.Remove Thermostat

1. Stop the engine and allow to cool. Loosen the coolant filler cap slowly to relieve any pressure and remove the cap.2. Drain the coolant from the cooling system to a level below the thermostat housing. 3. Loosen the hose clamps and remove the radiator hose from the thermostat housing. 4. Remove the thermostat and gasket from the thermostat housing.Install Thermostat

5. Install a new thermostat in the thermostat housing.

If the thermostat is installed wrong, it will cause the engine to overheat.

6. Install a new gasket and the water outlet pipe on the thermostat housing.7. Install the radiator hose and tighten the hose clamps.8. Add coolant to the cooling system to bring it to the proper level by mixing a solution of acceptable water, Caterpillar Antifreeze or equivalent and Supplemental Coolant Additive (Conditioner) if NOT using Caterpillar Antifreeze, or if equipped with a coolant conditioner element, install the appropriate element.Refer to the Cooling System - Clean/Flush Coolant topic