Rating:

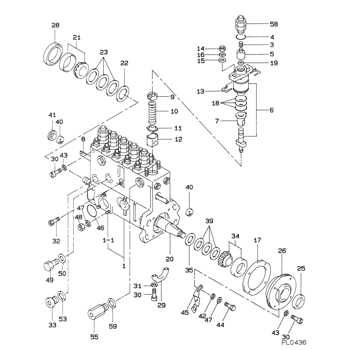

Information body assy, injecti Denso

KIT List:

Part name

Kit1

Kit2

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09010-08500

BODY ASSY, INJECTI

NB6

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09010-08500

BODY ASSY, INJECTI

Information:

Do not use more than 55 kPa (8 psi) of air pressure in the fuel tank or damage to the tank may result.

Check for leaks at the connection between the fuel tank and the fuel transfer pump. If leaks are found, tighten the connections or replace the lines. If there are no visual leaks, remove the fuel supply line from the tank and connect it to an outside furl supply. If this corrects the problem, the suction line (standpipe) inside the fuel tank has a leak.Water in the fuel can cause rough running and possible fuel system damage. Valve Adjustment Not CorrectCheck and make necessary adjustments as in Testing And Adjusting Section of the Service Manual. Intake valve lash is 0.38 mm (.015 in) and exhaust valve lash is 0.64 mm (.025 in). Also check for a bent or broken push rod. Defective Fuel Nozzle(s)Find a defective nozzle by running engine at the rpm where it runs rough. Loosen the fuel line nut at the through the head adapter enough to stop fuel supply to that cylinder. Each cylinder must be checked this way. If a cylinder is found where loosening of the nut makes no difference in the rough running, test the nozzle for that cylinder. To test a nozzle, remove the nozzle from the engine and test as in Testing and Adjusting Section of this Service Manual. Fuel Leakage From Fuel Injection Line NutTighten nut to 40 7 N m (30 5 lb ft). Again check for leakage. Be sure to check fuel injection lines inside valve cover base. Defective Fuel Injection PumpAn injection pump can have a good fuel flow coming from it but cause rough running because of slow timing that is caused by wear on the bottom end of the plunger. See the Testing and Adjusting Section in this Service Manual for the correct specifications and procedure to check plungers and lifters.Fuel pumps which are severely scored from debris can cause rough running but fuel dilution usually occurs before horsepower is affected.Low installation torque on the fuel pump retaining nut can cause misfire, rough running and low power. Fuel Has A High "Cloud Point"In cold weather operation this condition should be checked first. The fuel "cloud point" is the temperature at which wax begins to form in the fuel. If the atmospheric temperature is lower than the "cloud point" of the fuel, wax will form and plug the filter. Change the filter and drain the tank and the complete fuel system. The replacement fuel must be of a better grade with a lower "cloud point". Fuel Injection Timing Not CorrectCheck and make necessary adjustments as in Testing and Adjusting Section of this Service Manual. Automatic Timing Advance Does Not Operate CorrectlyCheck with engine warm. Use the 8T5300 Engine Timing Indicator Group and 8T5301 Diesel Timing Adapter Group. Special Instruction Form No. SEHS8580 has instructions and calibration procedures for this tool group. If the timing indicator group is not available, make rapid