Rating:

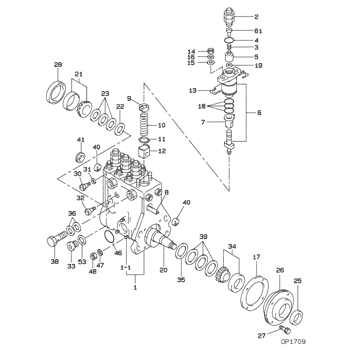

Information body assy, injecti Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09010-05952

BODY ASSY, INJECTI

NB4

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09010-05952

BODY ASSY, INJECTI

Information:

start by:a) remove oil pump Put identification numbers on the main bearing caps if the existing numbers can not be seen. Identification numbers are necessary for correct installation of the bearing caps.1. Remove the No. 2, No. 4 and No. 6 main bearing caps. 2. Use tool (A) to remove the upper halves of the main bearings. Put tool (A) in the crankshaft oil hole as shown. Turn the crankshaft in the direction which will push the tab end of the bearing out first.

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either or both.

3. Remove the lower halves of the bearings from the caps.4. Put clean SAE 30 engine oil on the bearings. Use tool (A) to install the upper halves of the bearings. Clean the bearing contact surface in the caps. Install the lower halves of the bearings in the caps. Put clean SAE 30 engine oil on the bearings and on the threads of all the bolts. When the bearing clearance is checked and the engine is in a vertical position, such as in the vehicle, the crankshaft will have to be lifted up and held against the upper halves of the main bearings to get a correct measurement with the Plastigage. The Plastigage will not hold the weight of the crankshaft and give a correct indication. If the engine is in a horizontal position, it is not necessary to hold the crankshaft up. Do not turn the crankshaft when the Plastigage is in position to check clearances. Do not tighten bolts with an impact wrench.5. Put plastigage (B) on the bearing to check the bearing clearance. Install the bearing caps and tighten the bolts to a torque of 30 3 lb.ft. (40 4 N m). Put a mark across the bolt heads and bearing caps, and turn each bolt 90° more from the mark. Remove the bearing caps and measure the thickness of the wire to find the bearing clearance. Clearance with new bearings must be .0030 to .0065 in. (0.076 to 0.165 mm). Maximum permissible clearance with used bearings is .010 in. (0.25 mm). The main bearing caps must be installed with the part number toward the front of the block. Make sure the number on the cap is the same number and on the same side as the number on the left side of the engine block.6. Put clean SAE 30 engine oil on the cap bolt threads, face of the washers and lower halves of the main bearings. Put the caps in position on the engine. Install the bolts and washers. Tighten the bolts to a torque of 30 3 lb.ft. (40 4 N m). Put a mark across the bolt heads and bearing, and tighten the bolts 90° more from the mark.7. Remove the No. 1, 3 and 5 main bearing caps. Do Steps 2 through 6

If the crankshaft is turned in the wrong direction, the tab of the bearing will be pushed between the crankshaft and cylinder block. This can cause damage to either or both.

3. Remove the lower halves of the bearings from the caps.4. Put clean SAE 30 engine oil on the bearings. Use tool (A) to install the upper halves of the bearings. Clean the bearing contact surface in the caps. Install the lower halves of the bearings in the caps. Put clean SAE 30 engine oil on the bearings and on the threads of all the bolts. When the bearing clearance is checked and the engine is in a vertical position, such as in the vehicle, the crankshaft will have to be lifted up and held against the upper halves of the main bearings to get a correct measurement with the Plastigage. The Plastigage will not hold the weight of the crankshaft and give a correct indication. If the engine is in a horizontal position, it is not necessary to hold the crankshaft up. Do not turn the crankshaft when the Plastigage is in position to check clearances. Do not tighten bolts with an impact wrench.5. Put plastigage (B) on the bearing to check the bearing clearance. Install the bearing caps and tighten the bolts to a torque of 30 3 lb.ft. (40 4 N m). Put a mark across the bolt heads and bearing caps, and turn each bolt 90° more from the mark. Remove the bearing caps and measure the thickness of the wire to find the bearing clearance. Clearance with new bearings must be .0030 to .0065 in. (0.076 to 0.165 mm). Maximum permissible clearance with used bearings is .010 in. (0.25 mm). The main bearing caps must be installed with the part number toward the front of the block. Make sure the number on the cap is the same number and on the same side as the number on the left side of the engine block.6. Put clean SAE 30 engine oil on the cap bolt threads, face of the washers and lower halves of the main bearings. Put the caps in position on the engine. Install the bolts and washers. Tighten the bolts to a torque of 30 3 lb.ft. (40 4 N m). Put a mark across the bolt heads and bearing, and tighten the bolts 90° more from the mark.7. Remove the No. 1, 3 and 5 main bearing caps. Do Steps 2 through 6