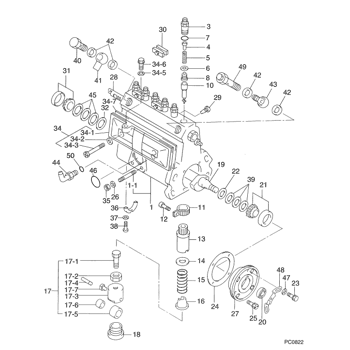

Rating:

Information body assy, injecti Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09010-04170

BODY ASSY, INJECTI

A6

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09010-04170

BODY ASSY, INJECTI

Information:

Introduction

On the machines listed above, the Delayed Engine Shutdown (DES) feature delays the engine from shutting off until the Diesel Exhaust Fluid (DEF) injector has cooled. Installing the DEF phase change tank decreases the frequency of the DES feature activating.Safety Section

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat® products.Dispose of all fluids according to local regulations and mandates.

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

Required Parts

Table 1

Required Parts

Item Qty Part Number Part Name

4 6 428-8808 Hose Clamp

5 1 467-9633 Hose

7 1 469-6277 Hose

8 1 424-1209 Tank

9 1 467-9636 Hose

10 1 6V-3250 O-Ring Seal

11 1 7X-1448 Elbow

12 1 454-4235 Plate

13 2 326-4516 Cable Tie

14 1 471-9825 Support As

15 2 8T-4189 Bolt

16 2 8T-4224 Hard Washer Installation Procedure

Illustration 1 g06123834

Remove support (1) from the engine compartment.

Illustration 2 g06123840

Locate insulation (2) on the engine hood.

Illustration 3 g06123843

Raise the insulation approximately 30 mm (1.2 inch) to avoid interference with the new tank.

Illustration 4 g06123848

Loosen the worm-drive clamps and remove two hoses (3) from the DEF system. Save the cushion clamps and hardware for reuse.

Illustration 5 g06123850

(4) 428-8808 Hose Clamp

(5) 467-9633 Hose

(6) Cushion clamp (reuse)

Install hose (5) and two clamps (4). Slowly tighten the clamps to 6.6 0.2 N m (58 1.8 lb in). Install cushion clamp (6) (previously removed) onto the hose.

Illustration 6 g06123852

(4) 428-8808 Hose Clamp

(6) Cushion clamp (reuse)

(7) 469-6277 Hose

(8) 424-1209 Tank

Connect one end of hose (7) to the tube on the engine using clamp (4). Slowly tighte

On the machines listed above, the Delayed Engine Shutdown (DES) feature delays the engine from shutting off until the Diesel Exhaust Fluid (DEF) injector has cooled. Installing the DEF phase change tank decreases the frequency of the DES feature activating.Safety Section

Do not perform any procedure in this Special Instruction until you have read the information and you understand the information.

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing, adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any compartment or disassembling any component containing fluids.Refer to Special Publication, NENG2500, "Dealer Service Tool Catalog" for tools and supplies suitable to collect and contain fluids on Cat® products.Dispose of all fluids according to local regulations and mandates.

Accidental engine starting can cause injury or death to personnel working on the equipment.To avoid accidental engine starting, disconnect the battery cable from the negative (−) battery terminal. Completely tape all metal surfaces of the disconnected battery cable end in order to prevent contact with other metal surfaces which could activate the engine electrical system.Place a Do Not Operate tag at the Start/Stop switch location to inform personnel that the equipment is being worked on.

Required Parts

Table 1

Required Parts

Item Qty Part Number Part Name

4 6 428-8808 Hose Clamp

5 1 467-9633 Hose

7 1 469-6277 Hose

8 1 424-1209 Tank

9 1 467-9636 Hose

10 1 6V-3250 O-Ring Seal

11 1 7X-1448 Elbow

12 1 454-4235 Plate

13 2 326-4516 Cable Tie

14 1 471-9825 Support As

15 2 8T-4189 Bolt

16 2 8T-4224 Hard Washer Installation Procedure

Illustration 1 g06123834

Remove support (1) from the engine compartment.

Illustration 2 g06123840

Locate insulation (2) on the engine hood.

Illustration 3 g06123843

Raise the insulation approximately 30 mm (1.2 inch) to avoid interference with the new tank.

Illustration 4 g06123848

Loosen the worm-drive clamps and remove two hoses (3) from the DEF system. Save the cushion clamps and hardware for reuse.

Illustration 5 g06123850

(4) 428-8808 Hose Clamp

(5) 467-9633 Hose

(6) Cushion clamp (reuse)

Install hose (5) and two clamps (4). Slowly tighten the clamps to 6.6 0.2 N m (58 1.8 lb in). Install cushion clamp (6) (previously removed) onto the hose.

Illustration 6 g06123852

(4) 428-8808 Hose Clamp

(6) Cushion clamp (reuse)

(7) 469-6277 Hose

(8) 424-1209 Tank

Connect one end of hose (7) to the tube on the engine using clamp (4). Slowly tighte