Rating:

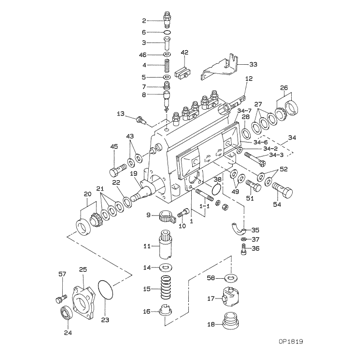

Information body assy, injecti Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09010-03922

BODY ASSY, INJECTI

A6

22110-1590

HINO

Include in ##:

09010-03922

as BODY ASSY, INJECTI

Cross reference number

Part num

Firm num

Firm

Name

09010-03922

22110-1590

BODY ASSY, INJECTI

Information:

Never use water alone as a coolant. Water alone is corrosive at engine operating temperatures. In addition, water alone does not provide adequate protection against boiling or freezing.

In engine cooling systems that use water alone, Caterpillar recommends the use of Cat SCA. Cat SCA helps to prevent the following conditions from occurring:

Corrosion

Formation of mineral deposits

Cavitation erosion of the cylinder liner

Foaming of the coolantIf Cat SCA is not used, select a fully formulated commercial SCA. The commercial SCA must provide a minimum of 2400 mg/L or 2400 ppm (140 grains/US gal) of nitrites in the final coolant mixture.The quality of the water is an important factor in this type of cooling system. Distilled water or deionized water is recommended for use in cooling systems. If distilled water or deionized water is not available, use water that meets or exceeds the minimum requirements that are listed in the table for recommended water properties in this Special Publication, "General Coolant Information" topic.A cooling system that uses a mixture of SCA and water only needs more SCA. The SCA concentration in a cooling system that uses SCA and water should be 6 to 8 percent by volume.Maintain the Cat SCA in the same way as you would maintain a cooling system that uses heavy-duty coolant/antifreeze. Adjust the maintenance for the amount ofCat SCA additions.Adding the Cat SCA to Water at the Initial Fill

Use the equation that is in this Special Publication, "Conventional Coolant/Antifreeze Cooling System Maintenance" to determine the amount of Cat SCA that is required at the initial fill. This equation is for a mixture of only Cat SCA and water.Adding the Cat SCA to Water for Maintenance

For the recommended service interval, refer to the Operation and Maintenance Manual, "Maintenance Interval Schedule" for your engine.Submit a coolant sample to your Cat dealer. See this Special Publication, "S O S Services Coolant Analysis" topic.Additions of Cat SCA are based on the results of the coolant analysis. The size of the cooling system determines the amount of Cat SCA that is required.Use the equation that is in this Special Publication, "Conventional Coolant/Antifreeze Cooling System Maintenance" to determine the amount of Cat SCA that is required for maintenance, if necessary:Note: Specific engine applications may require maintenance practices to be periodically evaluated in order to maintain properly the engine cooling system.SCA and part numbers are available from your Cat dealer.