Rating:

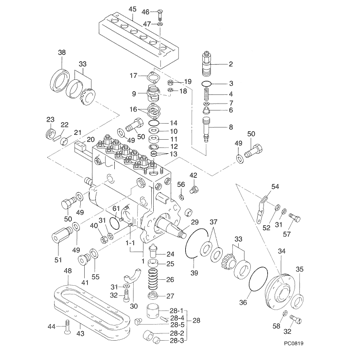

Information body assy, injecti Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09010-03710

BODY ASSY, INJECTI

P6

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09010-03710

BODY ASSY, INJECTI

Information:

Use Only Approved SCAs. Conventional coolants require the maintenance addition of SCA throughout their expected life. Do NOT use an SCA with a coolant unless specifically approved by the coolant supplier for use with their coolant. It is the responsibility of the coolant manufacturer to ensure compatibility and acceptable performance.Failure to follow the recommendations can result in shortened cooling system component life.

Cat SCA is compatible with Cat DEAC. If you use non-Cat brand conventional coolants, consult with the coolant manufacturer for information on a compatible SCA.

Do NOT mix brands or types of coolant. Do NOT mix brands or types of SCA and/or brands or types of extenders. Different brands or types may use different additive packages to meet the cooling system requirements. Different brands or types may not be compatible.Failure to follow the recommendations can reduce cooling system component life unless appropriate corrective action is performed.

If non-Cat conventional coolants that meet Cat minimum published requirements are used, confirm with the coolant manufacturer before using Cat SCA that Cat SCA is acceptable for use with the coolant. Do not exceed the 6 percent maximum concentration. Check the concentration of SCA with a SCA test kit, or check the concentration of SCA with Cat S O S coolant analysis.Cat engine cooling systems should be tested at 250 hour intervals or at the PM Level 1 intervals for the concentration of SCA (Supplemental Coolant Additive).Note: Acceptable conventional heavy-duty coolant/antifreeze of all types REQUIRE periodic additions of SCA.Follow the maintenance information provided in this Special Publication, "Coolant and General Maintenance Recommendations" section.Note: Specific engine applications may require maintenance practices to be periodically evaluated to maintain the engine cooling system properly.The availability of part numbers will vary from one region to another region.Do not exceed the 6 percent maximum concentration. Check the concentration of SCA with a SCA test kit, or check the concentration of SCA with Cat S O S coolant analysis.Adding the SCA to Pure Water or a Pure Water/Glycol Mixture at Initial Fill

For initial fill, Cat SCA added to pure water provides corrosion protection of the system. Ensure that the water meets quality requirements detailed in the Table “Cat Minimum Acceptable Water Requirements”, found in this Special Publication, "General Coolant Information". Also, ensure that the water or water/glycol mixture have not had additives previously added. Use the equation in Table 1 to determine the volume of the Cat SCA that is needed. The initial concentration of the SCA is recommended to be 7 percent. Once the coolant has been in service, maintain the SCA to a 3 to 6 percent range. Refer to the maintenance section for details.

Table 1

Equation For Adding The Cat SCA To Water At The Initial Fill

V × 0.07 = X

V is the total volume of the cooling system.

X is the amount of Cat SCA that is required. Table 2 is an example for using the equation that is in Table 1.

Table 2

Example Of The Equation For Adding The Cat SCA To Water At The Initial Fill

Total