Rating:

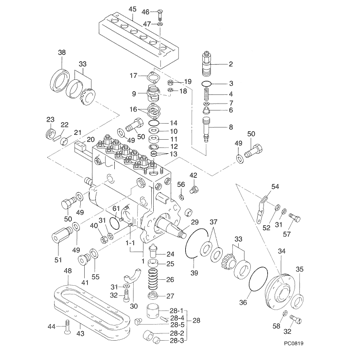

Information body assy, injecti Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09010-03090

BODY ASSY, INJECTI

P6

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09010-03090

BODY ASSY, INJECTI

Information:

Test 1 - Overspeed Switch (OS)

Table 1

Overspeed Switch (OS)

Step Engine RPM Action Correct Result

A 25 + 5 rpm less than 75% Overspeed Verify rpm Press the 75% Verify button No engine shutdown

B 25 + 5 rpm more than 75% Overspeed Verify rpm Press the 75% Verify button Air and fuel shutoff

C Manually reset the air shutoff lever at the top of the air inlet, if equipped. Press the ESS reset button. Test 2 - Emergency Stop Switch (ES)

Table 2

Emergency Stop Switch (ES)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Press the push button for the emergency stop switch Air and fuel shutoff

B Manually reset the air shutoff lever at the top of the air inlet, if equipped. Turn ES switch in the dirction that is shown on the face of the push button in order to reset the switch. Test 3 - Normal Stop Switch (NSS)

Table 3

Normal Stop Switch (NSS)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Push the normal stop switch (NSS) Fuel shutoff Test 4 - Water Temperature Contactor Switch

Table 4

Water Temperature Contactor Switch (WTS)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Place a jumper across terminals TS-2 and TS-7. Fuel shutoff

B Remove the jumper from terminals TS-2 and TS-7. Test 5 - Oil Pressure Switch (OPS1)

Table 5

Oil Pressure Switch (OPS1)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Place a jumper across terminals OPS1-1 and OPS1-3. Fuel shutoff

B Remove the jumper from terminals OPS1-1 and OPS1-3. Test 6 - Oil Pressure Switch (OPS2)

Table 6

Oil Pressure Switch (OPS2)

Step Engine RPM Action Correct Result

A 25 + 5 rpm less than the setting for the oil step speed Place a jumper across terminals OPS2-1 and OPS2-3. No engine shutdown.

B 25 + 5 rpm more than the setting for the oil step speed Place a jumper across terminals OPS2-1 and OPS2-3. Fuel shutoff 9 seconds after the oil step speed is reached.

C Remove the jumper from across terminals OPS2-1 and OPS2-3.

Table 1

Overspeed Switch (OS)

Step Engine RPM Action Correct Result

A 25 + 5 rpm less than 75% Overspeed Verify rpm Press the 75% Verify button No engine shutdown

B 25 + 5 rpm more than 75% Overspeed Verify rpm Press the 75% Verify button Air and fuel shutoff

C Manually reset the air shutoff lever at the top of the air inlet, if equipped. Press the ESS reset button. Test 2 - Emergency Stop Switch (ES)

Table 2

Emergency Stop Switch (ES)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Press the push button for the emergency stop switch Air and fuel shutoff

B Manually reset the air shutoff lever at the top of the air inlet, if equipped. Turn ES switch in the dirction that is shown on the face of the push button in order to reset the switch. Test 3 - Normal Stop Switch (NSS)

Table 3

Normal Stop Switch (NSS)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Push the normal stop switch (NSS) Fuel shutoff Test 4 - Water Temperature Contactor Switch

Table 4

Water Temperature Contactor Switch (WTS)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Place a jumper across terminals TS-2 and TS-7. Fuel shutoff

B Remove the jumper from terminals TS-2 and TS-7. Test 5 - Oil Pressure Switch (OPS1)

Table 5

Oil Pressure Switch (OPS1)

Step Engine RPM Action Correct Result

A Any rpm above the crank terminate rpm Place a jumper across terminals OPS1-1 and OPS1-3. Fuel shutoff

B Remove the jumper from terminals OPS1-1 and OPS1-3. Test 6 - Oil Pressure Switch (OPS2)

Table 6

Oil Pressure Switch (OPS2)

Step Engine RPM Action Correct Result

A 25 + 5 rpm less than the setting for the oil step speed Place a jumper across terminals OPS2-1 and OPS2-3. No engine shutdown.

B 25 + 5 rpm more than the setting for the oil step speed Place a jumper across terminals OPS2-1 and OPS2-3. Fuel shutoff 9 seconds after the oil step speed is reached.

C Remove the jumper from across terminals OPS2-1 and OPS2-3.