Rating:

Information body assy, injecti Denso

Scheme #.#:

№

Qty

Part num

Name

Remarks

Manufacture num

000

[01]

09010-01241

BODY ASSY, INJECTI

A4:DRIV.16.8

Include in ##:

Cross reference number

Part num

Firm num

Firm

Name

09010-01241

BODY ASSY, INJECTI

Information:

January 9, 2003

O-10

Priority PRODUCT IMPROVEMENT PROGRAM FOR INSTALLINGA NEW WIRE ASSEMBLY IN THE INJECTION ACTUATION PRESSURE CONTROL ON CERTAIN325C AND 325C L EXCAVATORS AND 950G II AND 962G II WHEEL LOADERS

1408 PI30431

This Program must be administered assoon as possible. When reporting the repair, use "PI30431" as the Partnumber and "7751" as the Group Number, "56" as the Warranty Claim DescriptionCode and "T" as the SIMS Description Code. Exception: If the repair isdone after failure, use "PI30431" as the Part Number, "7751" as the GroupNumber, "96" as the Warranty Claim Description Code, and "Z" as the SIMSDescription Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.

COMPLETION DATE

TERMINATION DATE

July 31, 2003 January 31, 2004PROBLEM

A new wire assembly needs to be installed in theinjection actuation pressure control on certain 325C and 325C L Excavatorsand 950G II and 962G II Wheel Loaders. The injection actuation pressurecontrol valve connector may have been assembled incorrectly some 3126BEngine harness. This can lead to intermittent engine operation or can causethe engine to stop. The wire assembly must be replaced.AFFECTED PRODUCT

Model Identification Number

325C L CRB465, 466, 468, 469

325C CSJ571, 572, 574, 578, 582, 586

950G II AYL587, 591, 592, 598-601,610, 612, 615AYB486-491

962G AYE459

962G II BAB336, 338PARTS NEEDED

1 - 2324367 Wire AssemblyACTION REQUIRED

See the attached Rework Procedure.SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs. Parts Labor Hrs. Parts Labor Hrs.

100% 1 0 0 0 0

This is a 1-hour job.PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAMAS SOON AS POSSIBLE.Attach. (1-Sample of Owner Notification)

(2-Rework Procedure)SAMPLE OF OWNER NOTIFICATION

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999PRIORITY - Install A New Wire Assembly In TheInjection Actuation Pressure ControlMODELS INVOLVED - 325C and 325C L Excavatorsand 950G II and 962G II Wheel LoadersDear Caterpillar Product Owner:A new wire assembly needs to be installed inthe injection actuation pressure control on certain 325C and 325C L Excavatorsand 950G II and 962G II Wheel Loaders. The injection actuation pressurecontrol valve connector may have been assembled incorrectly some 3126BEngine harness. This can lead to intermittent engine operation or can causethe engine to stop. The wire assembly must be replaced. A new wire assemblyneeds to be installed on the products listed below. You will not be chargedfor the service performed.Contact your local Caterpillar dealer immediatelyto schedule this service. The dealer will advise you of the time requiredto complete this service. Please refer the dealer to their Service Letterdated January 9, 2003 when scheduling this service.We regret the inconvenience this may causeyou, but urge you to have this service performed as soon as possible toprevent unscheduled downtime.Caterpillar Inc.

Identification #(s)Attached to January 9, 2003 Service Letter

Rework Procedure

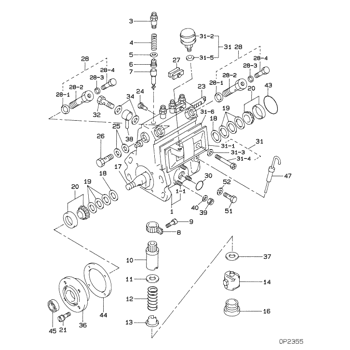

Disconnect the IAP control valve connector (seeIllustration 1).

Cut the wires behind the connector.

Strip the ends of both wires.

Install 2324367 harness by crimping the strippedwires inside the splice. Take care to connect pink wire to pink wire onone hand, purple wire to purple wire on the other hand.

Heat both heat shrinkable tubes in order to insulateboth splices.

Reconnect the

O-10

Priority PRODUCT IMPROVEMENT PROGRAM FOR INSTALLINGA NEW WIRE ASSEMBLY IN THE INJECTION ACTUATION PRESSURE CONTROL ON CERTAIN325C AND 325C L EXCAVATORS AND 950G II AND 962G II WHEEL LOADERS

1408 PI30431

This Program must be administered assoon as possible. When reporting the repair, use "PI30431" as the Partnumber and "7751" as the Group Number, "56" as the Warranty Claim DescriptionCode and "T" as the SIMS Description Code. Exception: If the repair isdone after failure, use "PI30431" as the Part Number, "7751" as the GroupNumber, "96" as the Warranty Claim Description Code, and "Z" as the SIMSDescription Code. The information supplied in this serviceletter may not be valid after the termination date of this program. Donot perform the work outlined in this Service Letter after the terminationdate without first contacting your Caterpillar product analyst.

COMPLETION DATE

TERMINATION DATE

July 31, 2003 January 31, 2004PROBLEM

A new wire assembly needs to be installed in theinjection actuation pressure control on certain 325C and 325C L Excavatorsand 950G II and 962G II Wheel Loaders. The injection actuation pressurecontrol valve connector may have been assembled incorrectly some 3126BEngine harness. This can lead to intermittent engine operation or can causethe engine to stop. The wire assembly must be replaced.AFFECTED PRODUCT

Model Identification Number

325C L CRB465, 466, 468, 469

325C CSJ571, 572, 574, 578, 582, 586

950G II AYL587, 591, 592, 598-601,610, 612, 615AYB486-491

962G AYE459

962G II BAB336, 338PARTS NEEDED

1 - 2324367 Wire AssemblyACTION REQUIRED

See the attached Rework Procedure.SERVICE CLAIM ALLOWANCES

Caterpillar Dealer Suggested Customer Suggested

Parts Labor Hrs. Parts Labor Hrs. Parts Labor Hrs.

100% 1 0 0 0 0

This is a 1-hour job.PARTS DISPOSITION

Handle the parts in accordance with your WarrantyBulletin on warranty parts handling.

MAKE EVERY EFFORT TO COMPLETE THIS PROGRAMAS SOON AS POSSIBLE.Attach. (1-Sample of Owner Notification)

(2-Rework Procedure)SAMPLE OF OWNER NOTIFICATION

XYZ Corporation

3240 Arrow Drive

Anywhere, YZ 99999PRIORITY - Install A New Wire Assembly In TheInjection Actuation Pressure ControlMODELS INVOLVED - 325C and 325C L Excavatorsand 950G II and 962G II Wheel LoadersDear Caterpillar Product Owner:A new wire assembly needs to be installed inthe injection actuation pressure control on certain 325C and 325C L Excavatorsand 950G II and 962G II Wheel Loaders. The injection actuation pressurecontrol valve connector may have been assembled incorrectly some 3126BEngine harness. This can lead to intermittent engine operation or can causethe engine to stop. The wire assembly must be replaced. A new wire assemblyneeds to be installed on the products listed below. You will not be chargedfor the service performed.Contact your local Caterpillar dealer immediatelyto schedule this service. The dealer will advise you of the time requiredto complete this service. Please refer the dealer to their Service Letterdated January 9, 2003 when scheduling this service.We regret the inconvenience this may causeyou, but urge you to have this service performed as soon as possible toprevent unscheduled downtime.Caterpillar Inc.

Identification #(s)Attached to January 9, 2003 Service Letter

Rework Procedure

Disconnect the IAP control valve connector (seeIllustration 1).

Cut the wires behind the connector.

Strip the ends of both wires.

Install 2324367 harness by crimping the strippedwires inside the splice. Take care to connect pink wire to pink wire onone hand, purple wire to purple wire on the other hand.

Heat both heat shrinkable tubes in order to insulateboth splices.

Reconnect the